TM 5-2410-241-10

0003

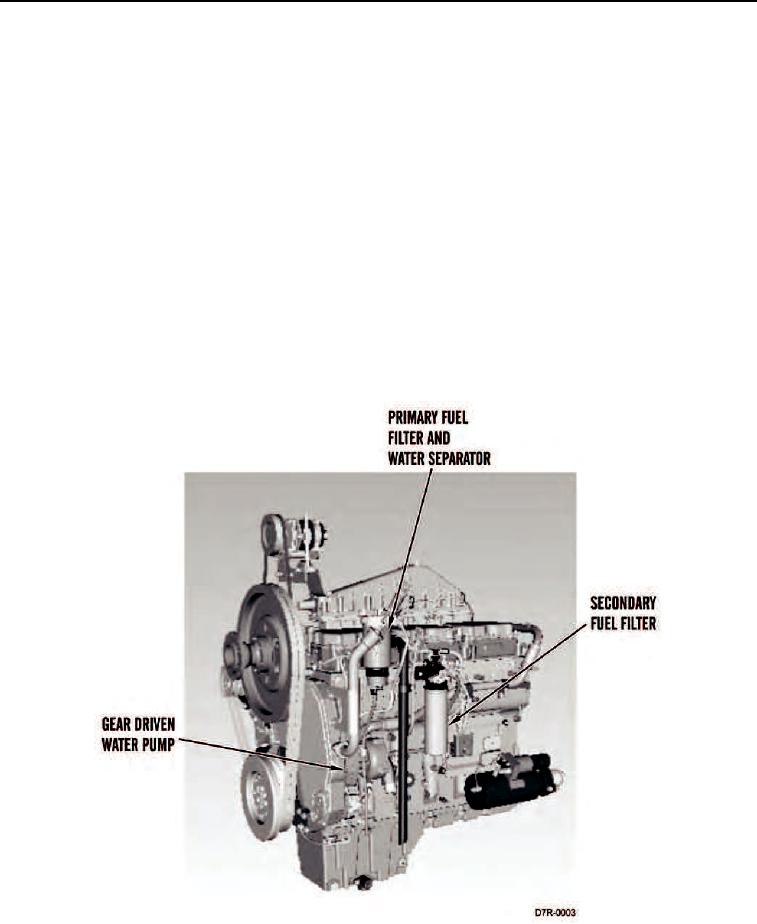

ENGINE

0003

General. The machine is equipped with a Caterpillar 3176C turbocharged diesel engine with six in-line cylinders,

generating 240 net horsepower @ 2,100 rpm.

Fuel System. Diesel fuel is drawn from the tank by a fuel transfer pump, filtered by a primary fuel filter, routed to

the fuel injection pump and secondary filter, and then injected through the fuel injector nozzles into the engine

cylinders. Air is drawn in through a precleaner, then through primary and secondary dry-type, replaceable filter

elements. A hose attached to the air cleaner directs incoming dust from the air filter and routes it out through the

exhaust system. The air is routed from the filter assembly to the turbocharger, which pressurizes the air and sends

it to the air-to-air aftercooler. The aftercooler, located near the radiator, reduces the air temperature, making it

denser. The denser air charge allows for more air and fuel to be combusted per engine cycle, increasing engine

output power.

Cooling System. Provides coolant to the engine. Coolant is circulated through the engine by a gear-driven water

pump. The hydraulic system oil cooler is located next to the radiator and aftercooler. The engine oil cooler is

externally mounted to the engine.

Lubrication System. The engine lubrication system consists of a gear-driven oil pump, oil filter, oil cooler, and oil

pan. The engine is lubricated by cooled and pressurized oil that is circulated through the engine block and head.

Exhaust System. The exhaust system removes exhaust gases from the engine through the exhaust manifold and

turbocharger. The gases flow through exhaust pipes and a muffler to the atmosphere.

Figure 1. Engine Components.

0003