TM 5-2410-240-23-1

0019

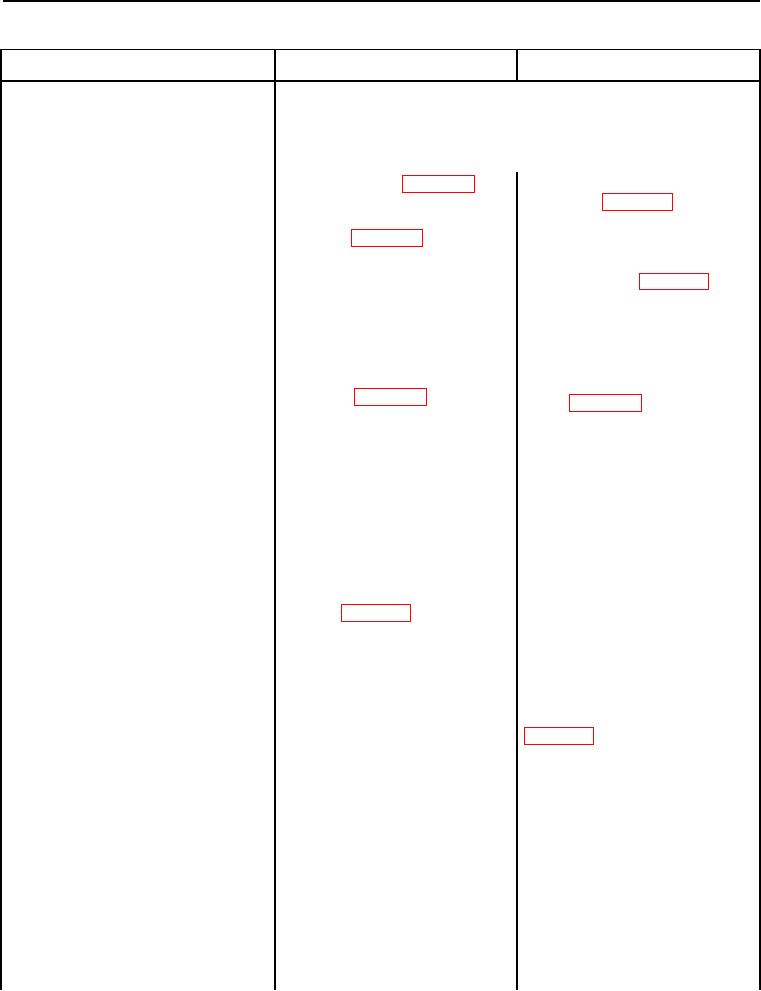

Table 1. Engine Troubleshooting Procedures - Continued.

0019

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

C AU T I O N

3. Engine Cranks But Will Not Start

Do not crank engine continuously for more than 30 seconds.

Allow starting motor to cool for two minutes before cranking

engine again.

1. Connect MSD (WP 0016).

Code Found - Troubleshoot diag-

Select engine ECM C6.6 D6K.

nostic code (WP 0013).

Check for any diagnostic

codes (WP 0013).

2. Check for correct battery volt-

Voltage Low - Troubleshoot Bat-

age.

tery Low Voltage (WP 0030).

3. Use MSD and ET to verify

Battery Cables OK - Replace

engine cranking speed. If

starter (WP 0095).

cranking speed is less than

Battery Cables Loose, Cor-

150 RPM, inspect for loose,

roded, or Damaged - Tighten

corroded, or damaged battery

loose connection, replace faulty

cables (WP 0030).

cables (WP 0030).

4. Make sure that primary, sec-

Faulty Primary Filter - Tighten/

ondary, and third fuel filters

replace primary fuel filter

are tight and secure.

(WP 0073).

Faulty Secondary Filter -

Tighten/replace secondary fuel fil-

ter (WP 0062).

Faulty Third Filter - Tighten/

replace third fuel filter (WP 0065).

5. Perform Prime Pump Flow

Engine Cranks But Will Not Start

Test (WP 0026).

- Proceed to step 6.

6. Inspect air intake and exhaust

system for the following

defects:

a. Blockages/Restrictions

Blockage/Restriction Found -

Remove blockages/restrictions

b. Damaged air intake and

Damage Found - Replace dam-

exhaust lines and hoses.

aged lines or hoses (WP 0040).