TM 5-2410-241-23-1

0004

FUEL SYSTEM CONTINUED

Injection

0004

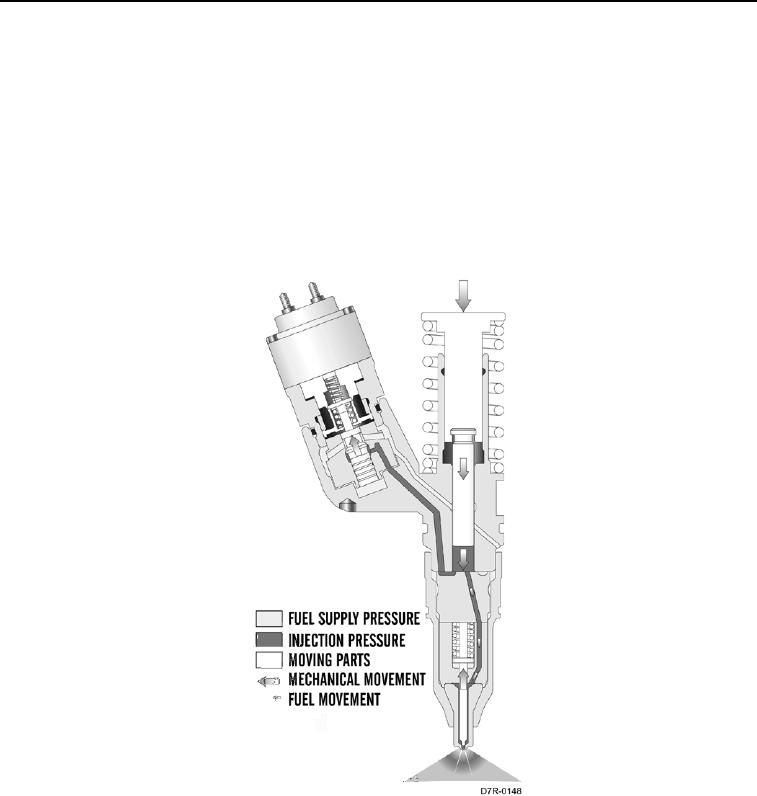

To start injection, the engine ECM sends a current to the solenoid on the cartridge valve. The solenoid creates a

magnetic field, which attracts the armature. When the solenoid is energized, the armature assembly will lift the

poppet valve so the poppet valve contacts the poppet seat. This is the closed position. Once the poppet valve

closes, the flow path for the fuel that is leaving the plunger cavity is blocked. The plunger continues to push fuel

from the plunger cavity and the fuel pressure builds up. When the fuel pressure reaches approximately 5,000 psi

(34,474 kPa), the force of the high pressure fuel overcomes the spring force. This holds the nozzle check in the

closed position. The nozzle check moves off the nozzle seat and the fuel flows out of the injector tip. This is the

start of injection.

Figure 9. Injection.

0004