TM 5-2410-241-23-1

0008

ELECTRICAL SYSTEM CONTINUED

Electronic Clutch Pressure Control (ECPC)

0008

Refer to Table 3.

0008

The ECM uses Electronic Clutch Pressure Control (ECPC) to control the movement of the machine. The ECM

uses five transmission clutch solenoid valves to enable shifting of the transmission. The transmission solenoid

valves control the hydraulic circuits that engage the transmission clutch pressures.

The ECM supplies electrical current to the appropriate transmission solenoid valve to move the machine in one of

the three available speeds in forward or reverse. In order to move the machine, the ECM will energize two clutch

solenoids, one for the direction and one for speed.

The ECM selects the transmission clutches that must be engaged according to the inputs from the operator

controls. The clutch pressure is modulated electronically. The ECM controls the modulation of clutch pressure by

sending a variable output current to the appropriate proportional clutch solenoids. The ECM uses input from the

transmission speed sensors, the torque converter output speed sensor and the transmission temperature sensor

in order to determine the correct output current in order to allow for the smooth engagement of the clutches.

The ECM will receive a pulse width modulated (PWM) signal in order to vary the current to the solenoid. The

current to the solenoid determines the amount of oil pressure that is applied to the clutch. The travel of the plunger

is proportional to the electrical current that is supplied to the solenoid. The position of the plunger controls the

amount of oil pressure and the amount of clutch engagement. An increase in electrical current will open the

solenoid valve further. This will cause an increase in oil pressure and an increase in clutch engagement pressure.

Transmission Shifting Operation

0008

The upshift switch, the downshift switch, and the position sensor for the direction lever, informs the ECM of the

shifting that is requested from the operator. The requests are "FORWARD," "NEUTRAL," "REVERSE," "UPSHIFT,"

or "DOWNSHIFT." The ECM activates the transmission solenoid valves in order to shift the transmission. Each

transmission clutch has a corresponding transmission solenoid valve. The transmission solenoid valves control the

hydraulic circuits that engage the transmission clutch pressures. The ECM applies electrical current to the

appropriate transmission solenoid valve. For the movement of the machine, two clutch solenoids are activated.

One solenoid is activated for the direction and one solenoid is activated for speed. Under normal conditions, the

ECM shifts the transmission based on the information from the forward/neutral/reverse (FNR) position sensor and

from the upshift and downshift switches.

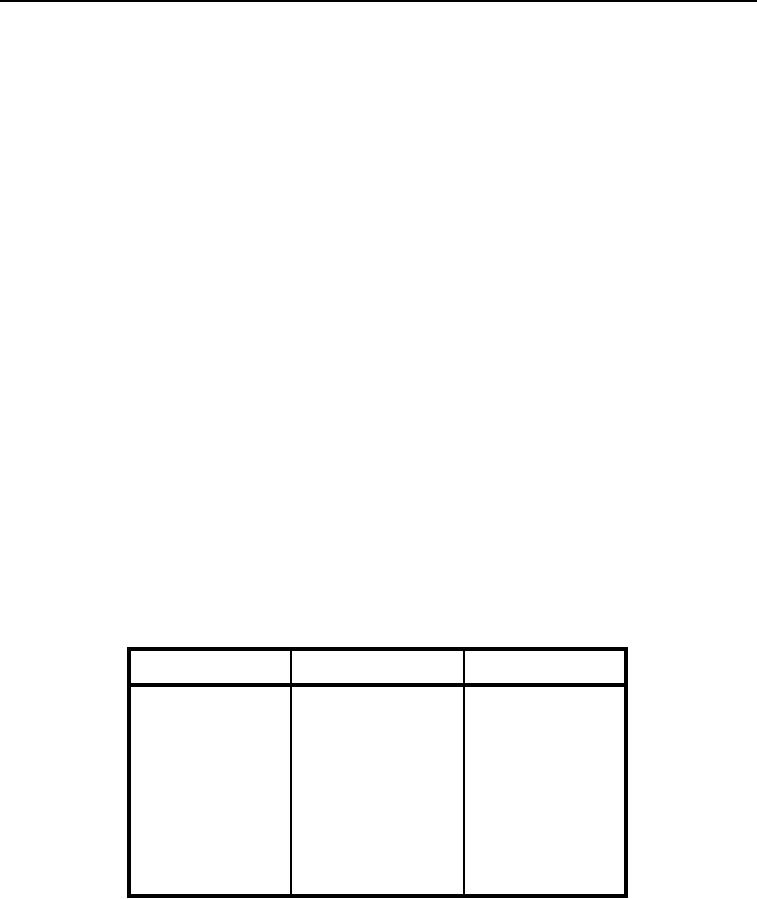

Table 3. Transmission Gear and Solenoid Valve Logic.

0008

Gear Engaged

Solenoid Valves On

Clutches Engaged

1F

5 and 2

5 and 2

2F

4 and 2

4 and 2

3F

3 and 2

3 and 2

Neutral

3

3

1F

5 and 1

5 and 1

2F

4 and 1

4 and 1

3F

3 and 1

3 and 1