TM 5-2410-241-23-1

0022

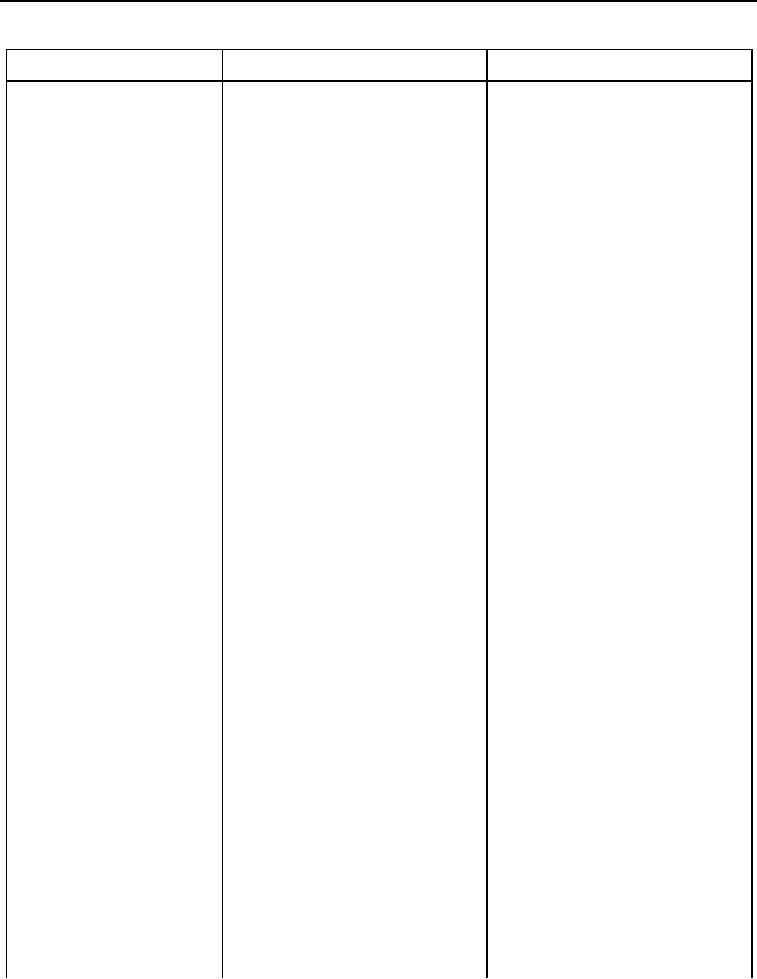

Table 1. Cab Troubleshooting Procedures - Continued.

0022

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

There is Little or No COLD

7. Low Pressure is Below Normal

1. If high pressure hose is NOT ser-

Airflow when Air Condi-

and High Pressure Reading

viceable - Replace high pressure

tioning is On - Contin-

Normal.

hose (WP 0241). Verify correct

ued

Remove high pressure hose

operation of machine (TM 5-2410-

(WP 0241) and inspect for a

241-10).

restriction.

2. If high pressure hose is service-

able, replace receiver-dryer orifice

tube (WP 0240). Verify correct

operation of machine (TM 5-2410-

241-10).

8. Low Pressure is Normal and

1. If high pressure hose is NOT ser-

High Pressure Reading is

viceable, replace high pressure

Above Normal

hose (WP 0241). Verify correct

Remove high pressure hose

operation of machine (TM 5-2410-

(WP 0241) and inspect for a

241-10).

restriction.

2. If high pressure hose is service-

able, replace receiver-dryer orifice

tube (WP 0240). Verify correct

operation of machine (TM 5-2410-

241-10).

9. Low Pressure is Normal and

1. If low pressure hose is NOT ser-

High Pressure Reading is

viceable, replace low pressure

BELOW Normal

hose (WP 0242). Verify correct

Remove low pressure hose

operation of machine (TM 5-2410-

(WP 0242) and inspect for a

241-10).

restriction.

2. If low pressure hose is service-

able, replace A/C compressor

(WP 0097). Verify correct opera-

tion of machine (TM 5-2410-241-

10).

10. Low Pressure Gauge Reading

Air is in the A/C system. Evacuate and

is Normal, and High Pressure

recharge A/C system. Refer to A/C

Gauge Bounces, or Gauge is

System Service (WP 0263). Verify

Unsteady

correct operation of machine (TM 5-

a. Low pressure gauge reading

2410-241-10).

is normal, but may drop into

vacuum range during the test.

b. High pressure gauge reading

is normal, but the low pres-

sure gauge reading is below

normal.

c.

Airflow from evaporator is

very cold, but will become

warm when low pressure

gauge drops into vacuum.

0022-112