TM 5-2410-240-23-1

0009

UNDERCARRIAGE SYSTEM CONTINUED

Track Roller

0009

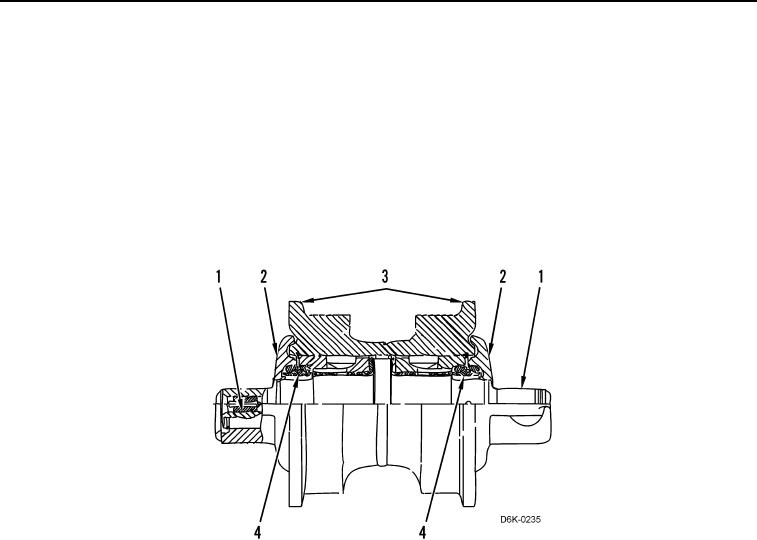

Seven double flange track rollers fasten to each track roller frame. The track rollers contact the inside surfaces of

the track links. The inside surfaces of the track links equally distribute the weight of the machine over the track.

Flanges (Figure 2, Item 3) prevent the track from moving side to side. Collars (Figure 2, Item 2) receive the side

load on the roller. Inside the center of the shaft (Figure 2, Item 1) is an oil reservoir. The oil in the reservoir

lubricates the bearing surfaces. Duo-Cone seals (Figure 2, Item 4) install on both ends of shaft.

N OT E

Shaft (1) end clearance (side movement) is not adjustable.

Figure 2. Track Roller.

0009

Track Carrier Roller

0009

The track carrier roller supports the track between the front idler and the sprocket. A roller support bracket fastens

to the track roller frame. A clamp holds the shaft (Figure 3, Item 1) in the roller support bracket. Movement of the

shaft inside the roller support bracket aligns the track carrier roller with the front idler and the sprocket. The roller

(Figure 3, Item 5) turns on two tapered roller bearings (Figure 3, Item 3).

The track carrier roller consists of the shaft (Figure 3, Item 1), Duo-Cone seal kit (Figure 3, Item 2), tapered roller

bearings (Figure 3, Item 3), cover (Figure 3, Item 4), roller assembly (Figure 3, Item 5), and collar assembly (Figure

3, Item 6).