TM 5-2410-240-23-1

0019

Table 2. Engine Troubleshooting with Codes - Continued.

0019

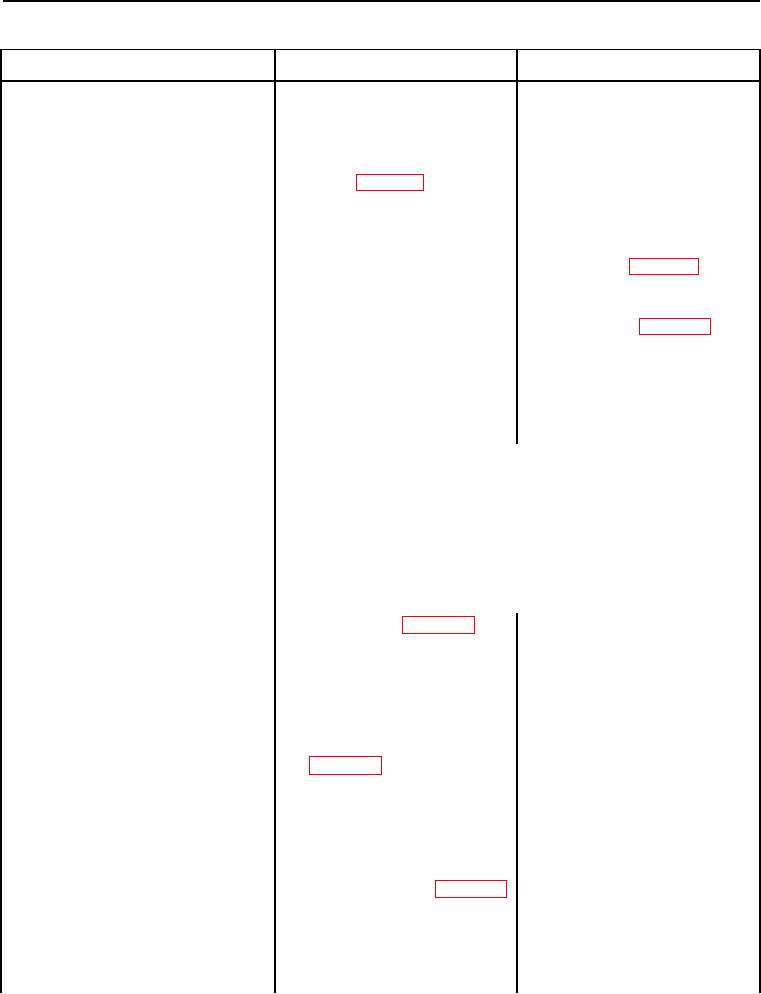

CID FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

0168-02 Electrical System Voltage

4. Using digital multimeter

Voltage within 18 - 24-Volts DC

Erratic, Intermittent, or Incorrect

(WP 0283), measure battery

Range - Replace fuel tank and

Continued

voltage supply circuit 150-RD

chassis wiring harness (WP 0153

for 18-24-Volts DC between

with ripper) (WP 0154 with winch).

circuit breaker box connector

Verify proper operation of machine

FP-C3 (WP 0018, Figure 168)

(TM 5-2410-240-10).

(circuit breaker side) terminal

Voltage Less than 18-Volts DC -

17 and ground.

Replace engine control circuit

breaker 8 (TM 5-2410-240-10).

Connect PL-C3 (WP 0018, Figure

216) to circuit breaker box (twist-

lock).

Connect EN-C13 (WP 0018,

Figure 130) to the engine ECM J2.

Verify proper operation of machine

(TM 5-2410-240-10).

0172-03 Intake Manifold Air Temper-

Test Step 1: Test Signal Circuit.

ature Sensor Voltage Above Normal

N OT E

Always inspect harness connectors that are involved in the

circuit. Poor connections can often be the cause of an electrical

circuit problem. Verify that all connections in circuit are clean and

secure, and connections are in good condition. If a problem with

connection is found, correct the problem and verify diagnostic

code is active before performing this procedure.

Tag wiring harnesses to aid installation.

1. Connect MSD (WP 0016).

Select engine ECM C6.6 D6K

and verify 0172-03 is active.

2. Turn ignition switch to the OFF

position (TM 5-2410-240-10).

3. Disconnect Air Intake Temper-

ature sensor E-C8

(WP 0018, Figure 109) har-

ness connector.

4. Turn ignition switch to ON

position (TM 5-2410-240-10).

5. Using digital multimeter

Voltage OK (5.0 0.5 Volts) -

(WP 0283), measure for volt-

Proceed to Test Step 2.

age between E-C8 (WP 0018,

Voltage Not OK - Proceed to Test

Figure 109) harness connec-

Step 3.

tor terminal 1 and ground.

Voltage should be 5.0 0.5

volts.