TM 5-2410-240-23-2

0169

RIGHT DRIVE LOOP HOSE REMOVAL

000169

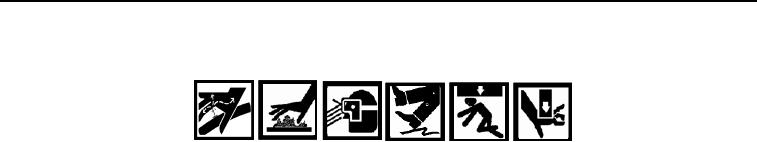

WARN I N G

DO NOT disconnect or remove any hydraulic system hoses, tubes, or fittings unless

engine is shut down and hydraulic system pressure has been relieved. Tighten all

connections before applying pressure. Escaping hydraulic fluid under pressure can

penetrate skin.

At operating temperature, hydraulic oil is hot. Allow hydraulic oil to cool before removing

any hydraulic fitting.

Wear protective eye covering and gloves.

Lubricating/hydraulic oils used in performance of maintenance can be very slippery.

Immediately wipe up any spills.

Failure to follow these warnings may result in injury or death to personnel.

C AU T I O N

Cap or plug all hydraulic hose ends and fittings during removal to protect against

contamination. Failure to follow this caution may cause damage to equipment.

N OT E

Hydraulic hoses, clamps, and fittings are all removed using the same general method.

This procedure covers removal of one hydraulic hose assembly from machine.

Tag and mark hose and fitting to aid installation.

Use a container to catch any fluid that may drain from hose or system. Dispose of fluid

IAW local policy and ordinances. Ensure all spills are cleaned up.

1. Using hydraulic line remover tool kit, disconnect hose (Figure 1, Item 2) from elbow (Figure 1, Item 1).

0169-2