TM 5-2410-241-23-1

0020

Table 1. Powertrain Troubleshooting Procedures - Continued.

0020

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

368-2 Autoshift Switch Data

1. Connect MSD (WP 0016), select

1. If active 368-2 code is present,

Erratic, Intermittent, or

Powertrain D7 ECM, and check for

proceed to step 4.

Incorrect

Diagnostic Codes or Event Codes

2. If active 368-2 code is NOT pres-

ent, proceed to step 2.

2. Activate Auto Shift Switch (TM 5-

2410-241-10).

3. Check for Diagnostic Codes or

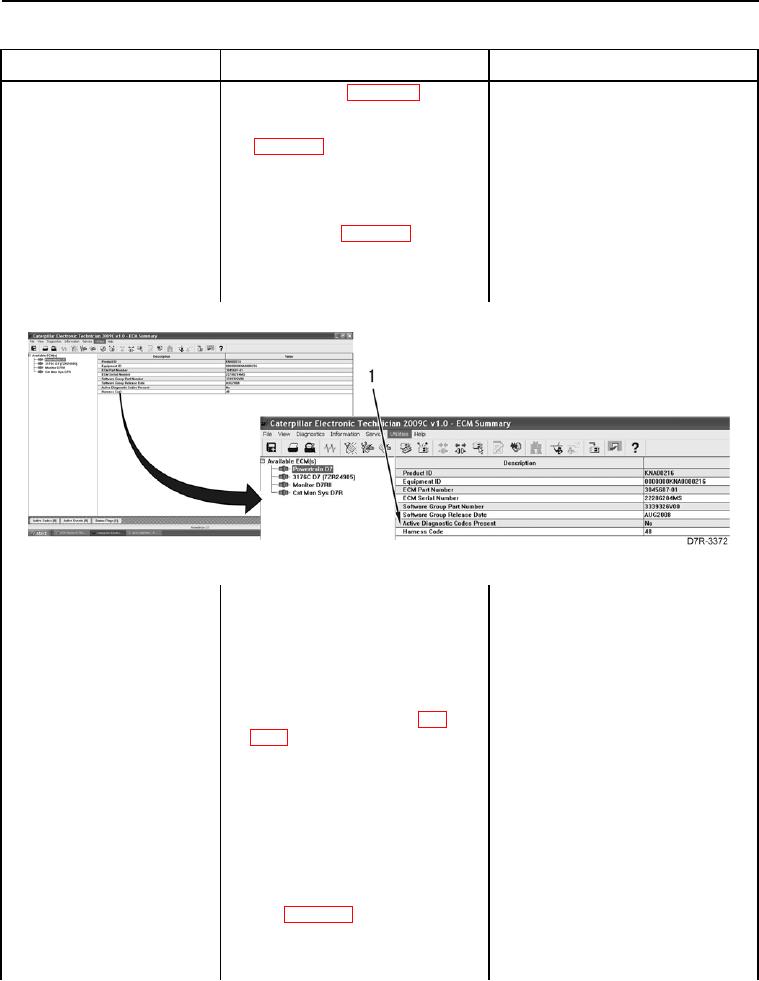

1. If active 368-2 code is present,

Event Codes (WP 0013) (Figure

proceed to step 4.

18, Item 1).

2. If no active code is present, the

problem does NOT exist at this

time. Resume normal operation.

Figure 18. Diagnostic Codes.

0020

4. Turn ignition switch and battery

disconnect switch to OFF position

(TM 5-2410-241-10).

5. Remove left platform access panel

(WP 0207).

6. Disconnect bi-directional mode

switch connector E-C11 (WP

0018, Figure 50) from auto shift

switch.

7. Turn ignition switch and battery

disconnect switch to ON position

(TM 5-2410-241-10).

8. Using a digital multimeter (WP

1. If voltage of 12.5 to 13.5 volts is

0296), measure for voltage

found, proceed to step 9.

between pins A and C on bi-direc-

2. If voltage of 12.5 to 13.5 volts is

tional mode switch connector E-

NOT found, proceed to step 10.

C11 (WP 0018, Figure 50).