TM 5-2410-241-23-2

0085

INSTALLATION

00085

C AU T I O N

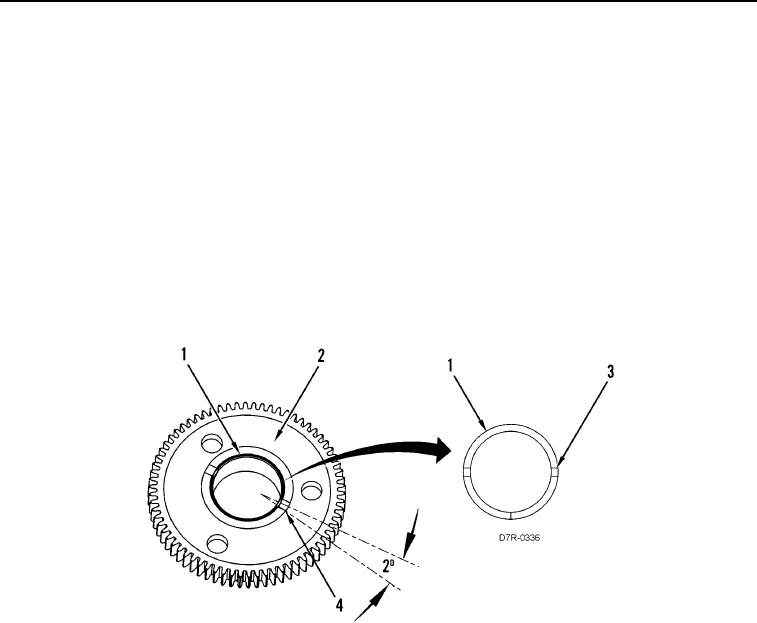

When installed, center of relief grooves on bearing must not be more than two degrees off

center of relief grooves on idler gear.

When installed, bearing must be flush with idler gear face on both sides of idler gear.

Failure to follow these cautions ma result in damage to equipment.

y

N OT E

The following step installs bearing on one idler gear. Repeat procedure to install bearing

on other idler gear.

1. Install bearing (Figure 9, Item 1) on idler gear (Figure 9, Item 2) with relief grooves (Figure 9, Item 3) on

bearing centered with relief joints (Figure 9, Item 4) on idler gear.

Figure 9. Idler Gear and Bearing.

0085