TM 5-2410-240-23-1

0010

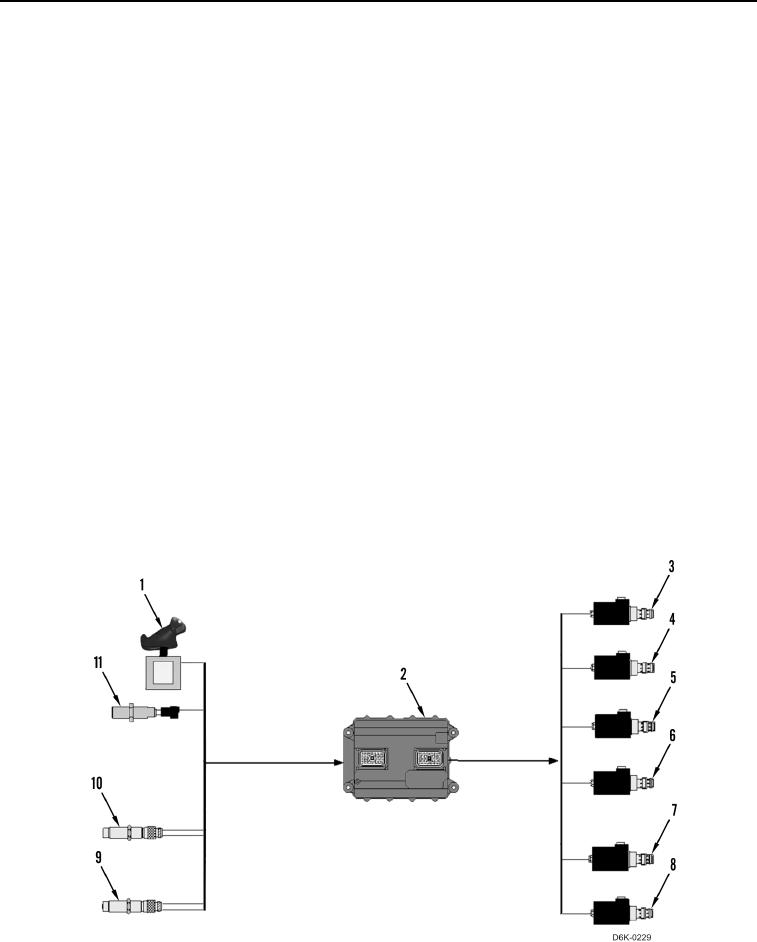

ELECTRO-HYDRAULIC CONTROLS CONTINUED

7. Left Pivot Turn

N OT E

The pivot turn is performed without brake engagement.

The machine ECM (Figure 13, Item 2) interprets two signals and determines that the joystick (Figure 13, Item 1) is

in the FORWARD and PIVOT LEFT position. The machine ECM sets the duty cycle for the motor displacement

control solenoid (Figure 13, Item 7) at less than 33% and the duty cycle for the motor displacement control

solenoid (Figure 13, Item 8) between 33% and 70%. These solenoids are located in the left and right hydrostatic

drive motors, respectively.

The machine ECM (Figure 13, Item 2) also sets the duty cycle for the reverse solenoid (Figure 13, Item 6) at less

than 23.5%, and the duty cycle for the forward solenoid (Figure 13, Item 4) between 26% and 88.5%. These

solenoids adjust the proportional solenoid valves in the right side hydrostatic pump.

The machine ECM (Figure 13, Item 2) also sets the duty cycle for the reverse solenoid (Figure 13, Item 5) at less

than 23.5% and the duty cycle for the forward solenoid (Figure 13, Item 3) at less then 26%. These solenoids

adjust the proportional solenoid valves in the left side hydrostatic pump.

N OT E

The duty cycles determine the angle of the pump and motor swashplates. The machine

ECM (Figure 13, Item 2) varies the duty cycles to the motor displacement solenoid

(Figure 13, Item 8) in the right hydrostatic drive motor, and to the forward solenoid

(Figure 13, Item 4) in the right side hydrostatic pump, based on signals received from the

travel speed switch in joystick (Figure 13, Item 1). The machine ECM also adjusts the duty

cycles based on signals received from the engine speed sensors (Figure 13, Item 11) and

motor speed sensors (Figure 13, Items 9 and 10) in order to prevent an overspeed,

underspeed, or stall condition, and to ensure the machine is tracking in a straight line.

Figure 13. Machine ECM Inputs and Outputs for Left Pivot Turn.

0010