TM 5-2410-240-23-1

0023

Table 1. Blade, Winch, and Ripper Troubleshooting Without Codes - Continued.

0023

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. Any Implement Moves

3. Inspect cylinder seals of affected

Cylinder Seal Leaks - (External

When Control Lever Is in

implement(s) for Class III leak.

Hose Leakage) - Repair affected cyl-

HOLD Position - Contin-

inder(s): Angle Cylinder (WP 0262);

ued

Tilt Cylinder (WP 0261); Lift Cylinder

(WP 0260); Ripper Cylinder (WP

0270), if equipped.

No External Seal Leakage - Proceed

to step 4.

4. Internal cylinder seals may be

Test Fails - Repair affected cylin-

leaking. If internal leakage is sus-

der(s): Angle Cylinder (WP 0262); Tilt

pected, verify component opera-

Cylinder (WP 0261); Lift Cylinder (WP

tion. Refer to Drift Tests and

0260); Ripper Cylinder (WP 0270), if

Speed Tests in Machine Opera-

equipped.

tion (WP 0033).

Test OK- Proceed to step 5.

Lines Leaking - Replace hydraulic

5. Inspect affected implement(s)

lines as necessary: Angle and Tilt

hydraulic lines between control

Tubes (WP 0157); Lift Cylinder Tubes

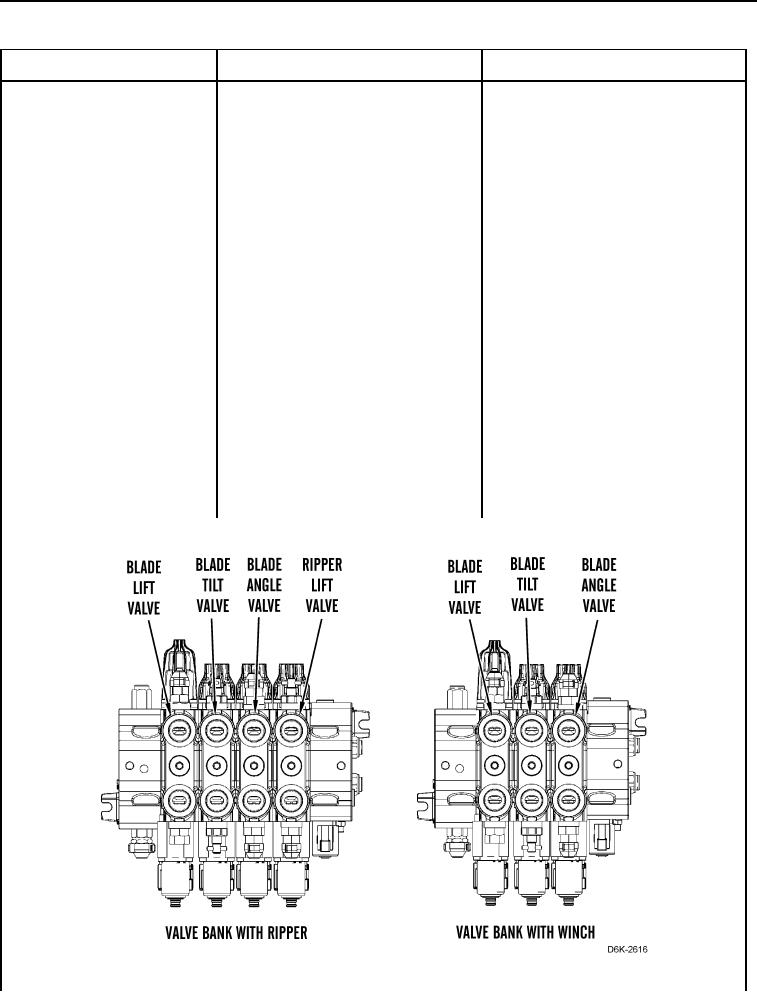

valve (Figure 1) and cylinders for

(WP 0172); Ripper (WP 0196).

leakage.

Lines Not Leaking - Replace affected

valve: Valve Bank 4 (Ripper) (WP

0196); Valve Bank 3 (Winch) (WP

0197) (Figure 1).

Figure 1. Valve Bank.

0023