TM 5-2410-241-23-1

0005

AIR INLET AND EXHAUST SYSTEM CONTINUED

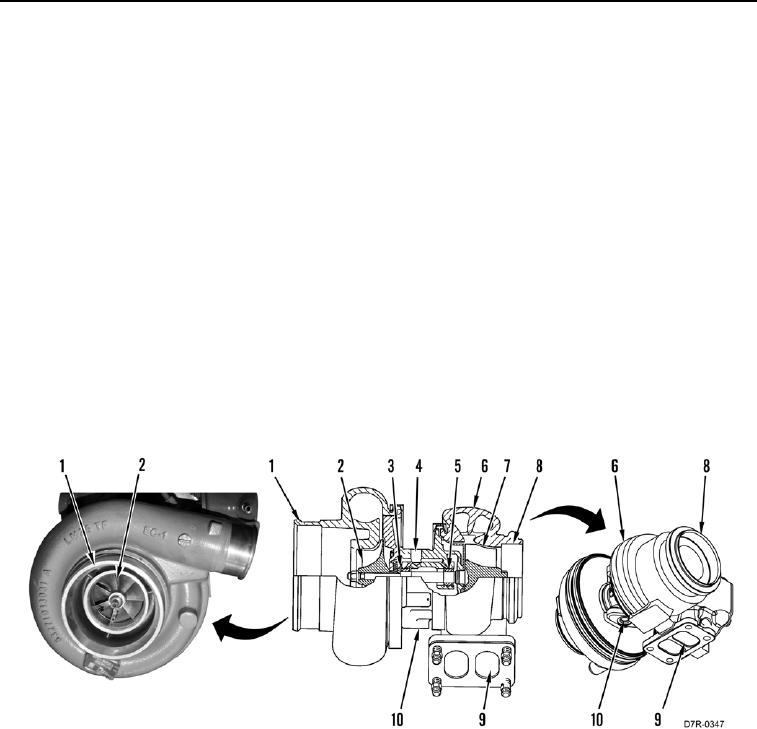

Turbocharger

0005

The turbocharger is installed on the center section of the exhaust manifold. All the exhaust gases from the engine

go through the turbocharger. The compressor side of the turbocharger is connected to the aftercooler by a pipe.

The exhaust gases enter turbine housing (Figure 2, Item 6) through exhaust inlet (Figure 2, Item 9). The exhaust

gases then push the blades of turbine wheel (Figure 2, Item 7) and exit the exhaust outlet (Figure 2, Item 8). The

turbine wheel is connected by a shaft to compressor wheel (Figure 2, Item 2).

Clean air from the air cleaner is pulled through the compressor housing air inlet (Figure 2, Item 1) by the rotation of

compressor wheel (Figure 2, Item 2). The action of the compressor wheel blades causes a compression of the inlet

air. This compression gives the engine more power by allowing the engine to burn more air and more fuel during

When the load on the engine increases, more fuel is injected into the cylinders. The combustion of this additional

fuel produces more exhaust gases. The additional exhaust gases cause the turbine and the compressor wheels of

the turbocharger to turn faster. As the compressor wheel turns faster, more air is forced into the cylinders. The

increased flow of air gives the engine more power by allowing the engine to burn the additional fuel with greater

efficiency.

Bearings (Figure 2, Items 3 and 5) for the turbocharger use engine oil under pressure for lubrication. The oil comes

in through the oil inlet port (Figure 2, Item 4). The oil then goes through passages in the center section in order to

lubricate the bearings. Oil from the turbocharger goes out through the oil outlet port (Figure 2, Item 10) in the

bottom of the center section. The oil then goes back to the engine lubrication system.

Figure 2. Turbocharger.

0005