TM 5-2410-241-23-1

0008

ELECTRICAL SYSTEM CONTINUED

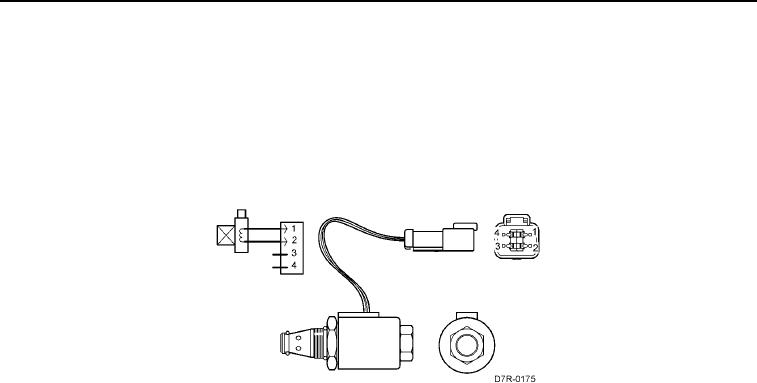

Proportional Brake Solenoid

0008

Refer to Table 5.

0008

The ECM uses the brake proportional solenoid to engage or disengage the service brakes. It receives a PWM input

signal from the brake pedal position sensor and outputs a proportional PWM signal to energize the solenoid. The

ECM will control the amount of electrical current that is sent to the solenoid depending on the position of the brake

pedal. The service brakes are spring applied and hydraulically released.

Figure 19. Proportional Brake Solenoid.

0008

When the machine is operating and the service brake pedal is not depressed, the ECM will send the maximum

current to the solenoid in order to disengage the service brakes. As the brake pedal is depressed, the ECM will

DECREASE the current signal to the solenoid, which will cause the brakes to be applied. As the travel of the brake

pedal is increased, the ECM will continue to DECREASE the current signal that is sent to the solenoid. This will

cause the service brakes to increase the force of engagement.