TM 5-2410-241-23-1

0019

Table 2. Engine Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

168-2 System Voltage Inter-

24. Using digital multimeter

1. If continuity is found, proceed to

mittent/Erratic -

(WP 0296), test for continuity

step 25.

Continued

between pin 65 on ECM harness

2. If continuity is not found, replace

connector V-C4 (WP 0018,

ECM harness (WP 0105). Ensure

Figure 1) and ground.

all harness connectors are recon-

nected. Verify correct operation of

machine (TM 5-2410-241-10).

25. Disconnect ECM harness connec-

tor MA-C3 (WP 0018, Figure 21)

from fuse panel harness connec-

tor A-C1 (WP 0018, Figure 22).

26. Using digital multimeter

1. If continuity is found, proceed to

(WP 0296), test for continuity

step 27.

between pin 11 on ECM harness

2. If continuity is not found, replace

connector MA-C3 (WP 0018, Fig-

platform harness (WP 0209).

ure 21) and pin 2 on ECM har-

Ensure all harness connectors

ness connector MA-C22 (WP

are reconnected. Verify correct

0018, Figure 11).

operation of machine (TM 5-2410-

241-10).

27. Using digital multimeter

1. If continuity is found, proceed to

(WP 0296), test for continuity

step 28.

between pin 12 on ECM harness

2. If continuity is not found, replace

connector MA-C3 (WP 0018,

platform harness (WP 0209).

Figure 21) and pin 11 on ECM

Ensure all harness connectors

harness connector MA-C22

are reconnected. Verify correct

(WP 0018, Figure 11).

operation of machine (TM 5-2410-

241-10).

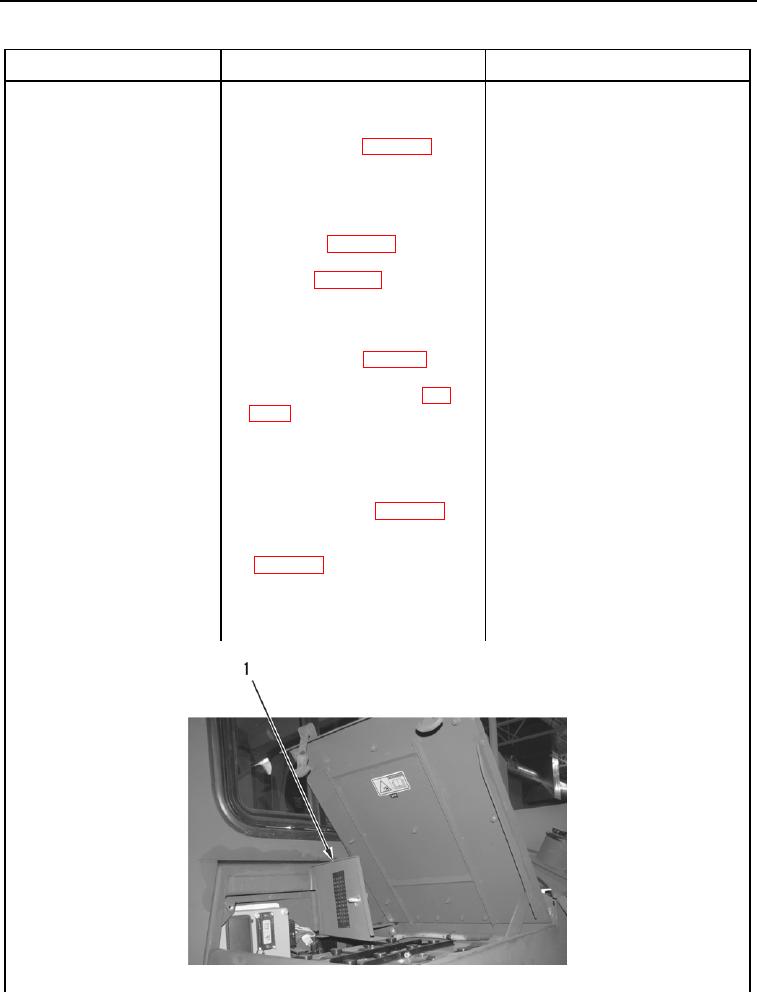

28. Open fuse panel door

(Figure 12, Item 1).

Figure 12. Fuse Panel Door.

019