TM 5-2410-241-23-1

0020

Table 1. Powertrain Troubleshooting Procedures - Continued.

0020

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

468-8 Service Brake Pedal

21. Using a digital multimeter (WP

1. If continuity is found, proceed to

Position Sensor Signal

0296), test for continuity between

step 22.

Abnormal - Continued

pin 3 on platform harness connec-

2. If continuity is NOT found, replace

tor MA-C3 (WP 0018, Figure 21)

platform harness (WP 0209) and

and pin A on dash harness brake

instrument panel harness (WP

position sensor connector E-C27

0260). Ensure all harness connec-

(WP 0018, Figure 52).

tors are reconnected. Verify cor-

rect operation of machine (TM 5-

2410-241-10).

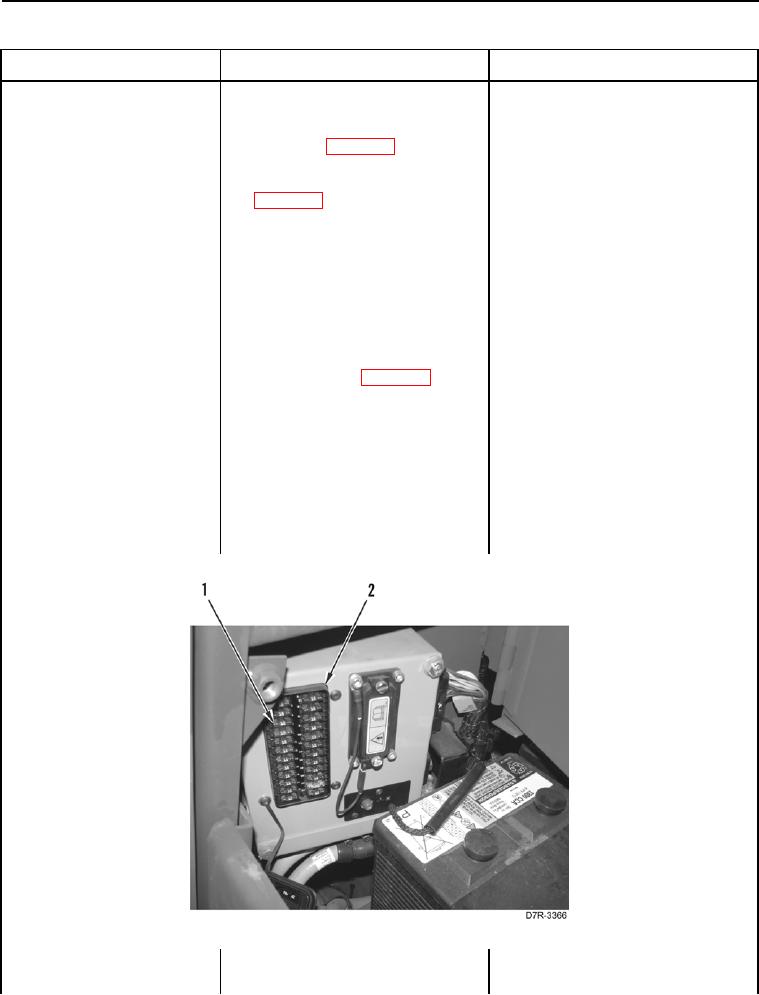

22. Remove Fuse #5 (Figure 28,

Item 1) from fuse panel (Figure 28,

Item 2) (TM 5-2410-241-10).

23. Using a digital multimeter (WP

1.

If continuity is found, replace pow-

0296), test for continuity between

ertrain ECM (WP 0175). Install

pin 3 on fuse panel wiring harness

Fuse #5 on fuse panel. Ensure all

connector A-C1 (WP 0018, Figure

harness connectors are recon-

22) and left cavity of Fuse #5 (Fig-

nected. Verify correct operation of

ure 28, Item 1) on fuse panel (Fig-

machine (TM 5-2410-241-10).

ure 28, Item 2).

2.

If continuity is NOT found, replace

fuse panel harness (WP 0176).

Install Fuse #5 on fuse panel.

Ensure all harness connectors are

reconnected. Verify correct opera-

tion of machine (TM 5-2410-241-

10).

Figure 28. Fuse #5.

0020