TM 5-2410-241-23-1

0039

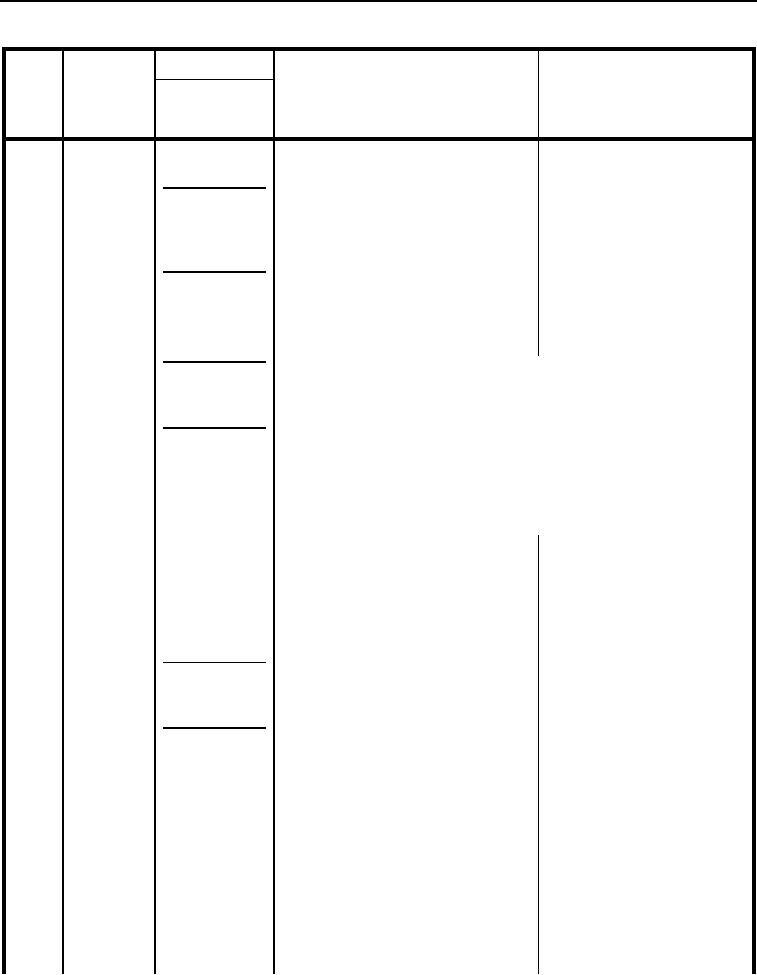

Table 1. Preventive Maintenance Checks and Services (PMCS) - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

NOT FULLY MISSION

SERVICE

NO.

INTERVAL

PROCEDURE

CAPABLE IF:

Inspect Rollover Protective Structure

20

1,000 Hours

Loose, missing, or damaged

Rollover

or Semi-

for bolts that are missing, loose, or

bolts. Cracks in welds and

Protective

Annually

damaged. Replace missing or

seams.

Structure

damaged bolts. Replace ROPS if

(ROPS)

cracks in welds and seams are

detected (WP 0225).

Do not weld reinforcement plates to

ROPS/FOPS in order to straighten

ROPS/FOPS structure.

C AU T I O N

21

Every 2,000

Engine Valve

Service

Lash - Check/

Operating the engine with improper valve adjustments will

Hours

Adjust

reduce engine efficiency. This reduced efficiency could result in

Annually

excessive fuel usage and/or shortened engine component life.

N OT E

Measure valve clearance with engine stopped. To obtain an

accurate measurement, allow at least 20 minutes for valves to

cool to engine cylinder head and engine block temperature.

a. Check valve bridge before setting Valves not adjustable or worn.

valve lash. Ensure that valve bridge is

seated equally on both valve stems.

Refer to WP 0107.

b. Check engine valve lash and adjust

as required, refer to WP 0107.

a. Improperly operating valve rotor will Valve rotator worn or damaged.

22

Every 2,000

Engine Valve

Service

shorten valve life because of

Rotators -

Hours

accelerated wear on valves. Metal

Inspect

annually

particles from a damaged valve rotator

could fall into cylinder and damage to

piston head and cylinder head may

result. Refer to WP 0107.

b. Start engine and run at low idle.

Watch top surface of each valve

rotator. Whenever an inlet valve or

exhaust valve closes, each valve

rotator should turn. Refer to WP 0107.

c. Check engine valve lash and adjust

as required, refer to WP 0107.

0039-20