TM 5-2410-241-23-2

0102

REMOVAL CONTINUED

N OT E

Once removed, rear crankshaft seal must be replaced.

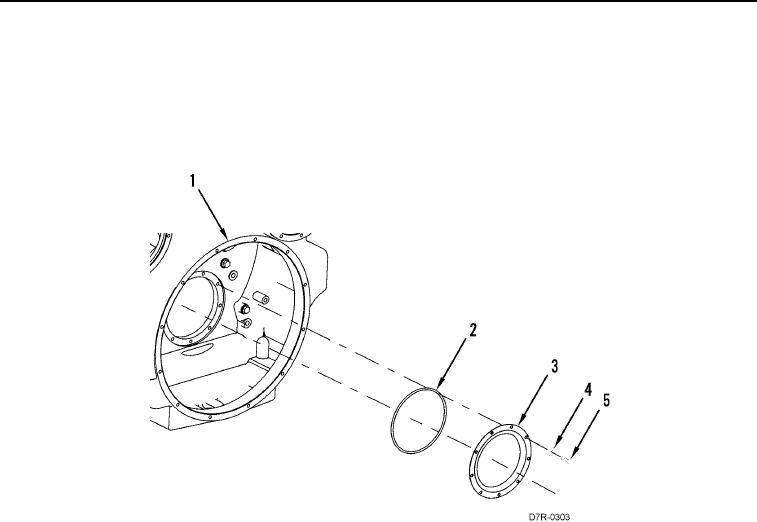

2. Remove nine bolts (Figure 2, Item 5), washers (Figure 2, Item 4), rear crankshaft seal (Figure 2, Item 3), and

O-ring (Figure 2, Item 2) from flywheel housing (Figure 2, Item 1). Discard rear crankshaft seal and O-ring.

Figure 2. Rear Crankshaft Seal, O-ring Seal, and Retaining Hardware.

0102

END OF TASK

CLEANING AND INSPECTION

000102

Clean and inspect all parts IAW Mechanical General Maintenance Instructions (WP 0295).

END OF TASK

INSTALLATION

000102

C AU T I O N

Do not install rear crankshaft seal without plastic sleeve. Seal damage and oil leakage

may result.

Do not lubricate rear crankshaft seal or cran shaft flange. Rear crankshaft seal must be

k

installed dry or oil leakage may result.

N OT E

Replacement rear crankshaft seal includesplastic sleeve, which protects seal lip during

installation. Do not remove plastic sleeve, it will be forced off during installation.

Ensure mounting flange is clean, dry, and free from damage.

Ensure plastic sleeve is squarely insalled within new rear crankshaft seal.

t