TM 5-2410-240-10

0012

Table 1. Preventive Maintenance Checks and Services (PMCS) - Continued

LOCATION

ITEM TO BE

CHECKED

OR

EQUIPMENT NOT

ITEM

MAN-

SERVICED

PROCEDURE

READY/AVAILABLE IF:

NO.

INTERVAL HOURS

14

Before

Winch

Check winch assembly for

Class III leaks or damage

damage, fluid leaks, wear, or

that would impair operation

visible cable damage. Refer to

if required for mission.

TB 43-0142.

15

Before

Ripper

a. Check ripper hydraulic cylinder

Class III leaks, damage that

would impair operation, or

for leaks.

missing or worn ripper teeth

b. Check frame and teeth for

if required for mission.

excessive debris, wear, damage, or

missing components.

16

Before

Lights

Check rear worklights for missing,

Missing, inoperative, or

damaged components if

inoperative, or damaged

required for mission.

components.

RIGHT SIDE

17

Before

Overall View

Check right side of machine for

Class III leaks or damage

evidence of leakage or damage.

that would impair operation

are evident.

18

Before

Angle

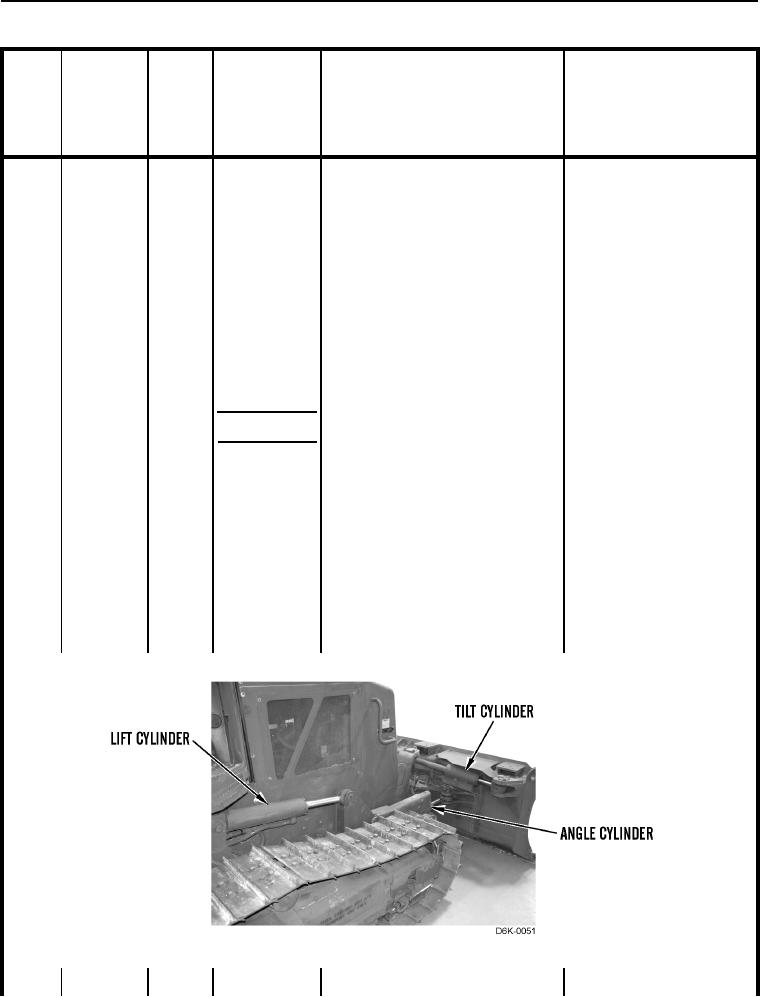

a. Check blade angle, lift, and tilt

Damaged components or

Cylinder, Lift

cylinders for debris, leakage, or

Class III leaks.

Cylinder, Tilt

damage.

Cylinder,

b. Check angle, lift, and tilt

Angle/Lift/Tilt

cylinder lines and fittings for

Cylinder Lines

leakage or damage.

and Fittings

Figure 11.

Blade Cylinder Inspection.

0012