2

TM 5-2410-240-10

OPERATOR MAINTENANCE

-

FRONT IDLER POSITION INSPECTION

00

16

Inspection

INITIAL SETUP

Equipment Condition

Tools and Special Tools

0

0

RULE, MACHINIST'S, 6 IN.

Machine parked (WP 0005)

0

(WP 0021, Item 11)

0

Estimated Time to Complete

0

0.1 Hr

0

INSPECTION

00016

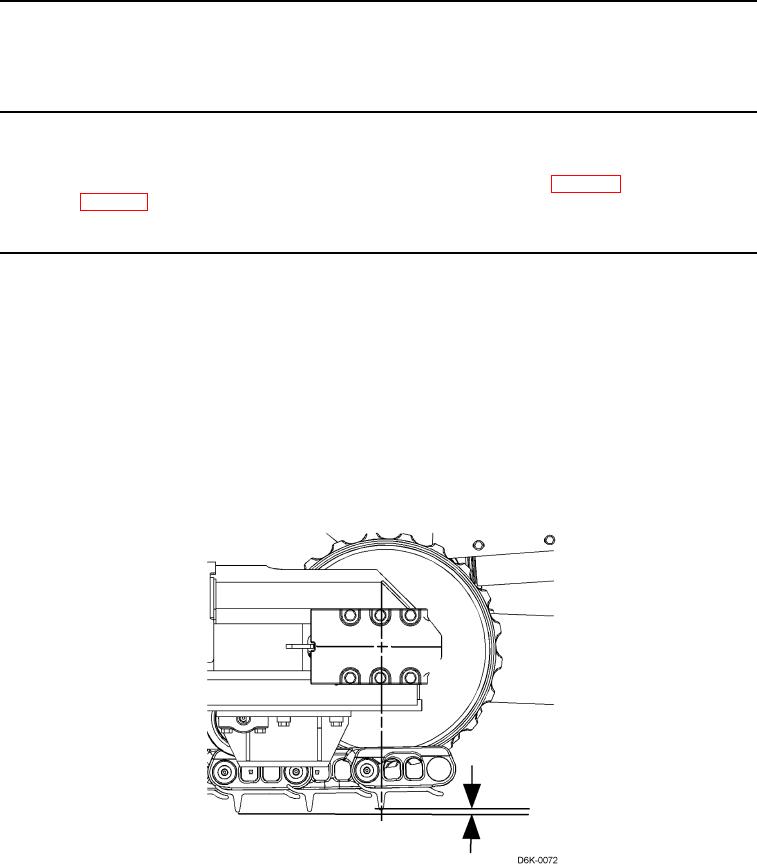

1. Ensure machine is parked on a hard, flat surface. Ensure bottom of track is tight and that grouser to be mea-

sured is directly below track idler shaft (Figure 1, Item 1).

C AU T I O N

Do not take measurement at outside corner tip of grouser. Grouser may be worn. Take

measurement at least two inches in from outside edge of grouser tooth to ensure

accuracy.

2. Measure distance from ground to tip of grouser.

a. If measurement is between 0.2 - 0.6 in. (5-16 mm), no adjustment is necessary.

b. If measurement is less than 0.2 in. (5 mm) or greater than 0.6 inches (16 mm), front idler requires adjust-

ment. Notify Field Maintenance.

Figure 1. Front Idler Position Inspection.

0016

END OF TASK

END OF WORK PACKAGE

0016-1/(2 blank)