TM 5-2410-241-23-1

0009

PRIMARY POWERTRAIN CONTINUED

Service Brake Pedal Operation

0009

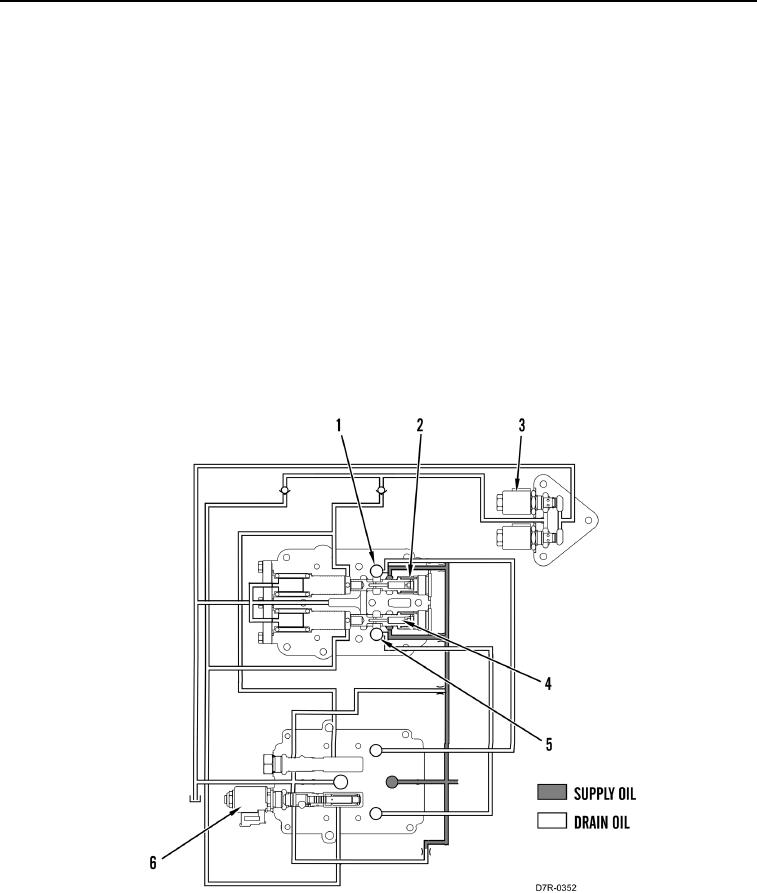

When the operator pushes the service brake pedal toward the floor, the rotary sensor sends a signal to the ECM.

This signal tells the ECM the brake pedal position. The ECM decreases the current to proportional valve

(Figure 17, Item 6) relative to the brake pedal position.

The decreased current reduces pilot oil pressure, which moves reducing spools (Figure 17, Item 2) and (Figure 17,

Item 4) to the left. The movement drains the oil in both brake circuits (Figure 17, Item 1) and (Figure 17, Item 5).

When the oil is drained, the brake oil pressure is lowered.

The current to the proportional solenoid valve is dependent upon the position of the brake pedal. The solenoid sets

the pilot oil pressure. The pressure in the brake circuit is directly affected by the position of the brake pedal.

When the brake pedal is partially depressed, the pilot pressure is reduced. The machine brakes lightly. When the

brake pedal is fully depressed, the pilot pressure is reduced until the pressure reaches zero psi (kPa). The oil is

drained from the brake circuit. The machine brakes fully.

Once the pedal is to the floor, the switch (end of travel) for the service brake opens. The switch connects one of the

secondary solenoid valves (Figure 17, Item 3) to the battery. The ECM sends an electrical signal to the other

secondary solenoid valve (Figure 17, Item 3). The energized solenoid valves move reducing spools (Figure 17,

Item 2) and (Figure 17, Item 4) to the left. The movement routes the oil in both brake circuits (Figure 17, Item 1) and

(Figure 17, Item 5) to the drain. When the pilot oil is drained, the machine brakes fully.

Figure 17. Brake Control Valve.

0009