TM 5-2410-241-23-1

0020

Table 1. Powertrain Troubleshooting Procedures - Continued.

0020

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

N OT E

1403-3 Transmission Sole-

noid Valve #3 Voltage

It may be necessary to remove winch (if equipped) to access transmis-

Above Normal - Contin-

sion solenoid valves.

ued

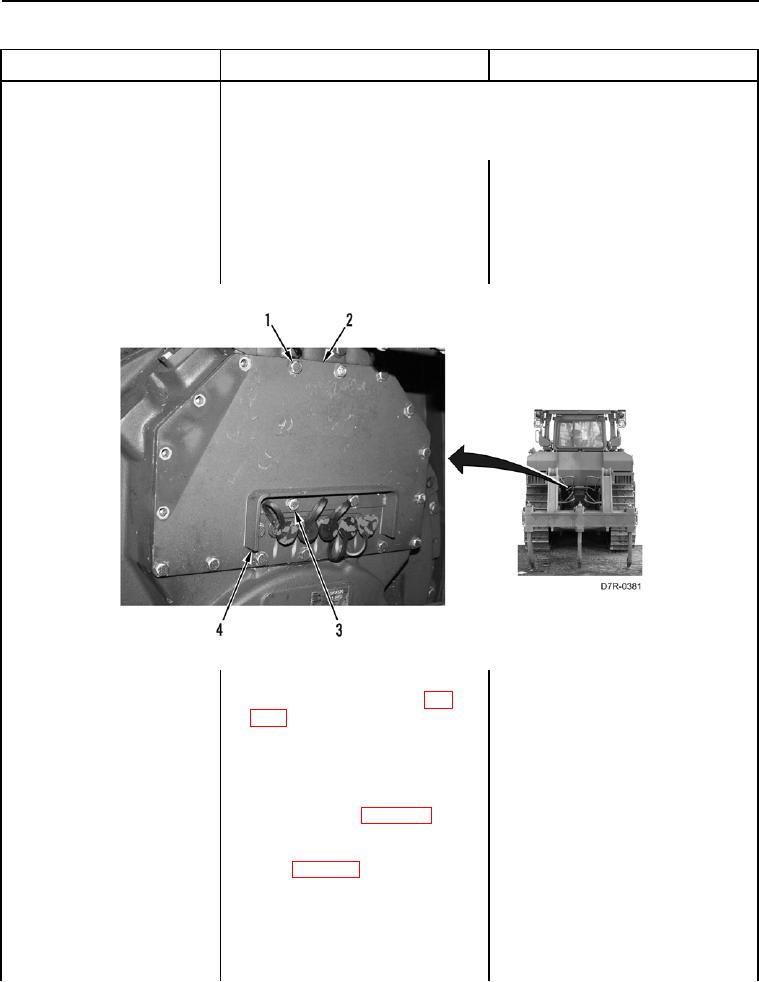

18. Remove two bolts (Figure 56,

Item3) and guard (Figure 56,

Item4) from machine.

19. Remove 15 bolts (Figure 56,

Item1) and plate (Figure 56,

Item 2) from machine.

Figure 56. Guard, Plate, and Retaining Hardware.

0020

20. Disconnect transmission solenoid

valve #3 connector P-C7 (WP

0018, Figure 73) from transmis-

sion solenoid valve #3 (WP 0145).

21. Using a digital multimeter (WP

1. If continuity is found, replace pow-

0296), test for continuity between

ertrain ECM (WP 0175). Ensure all

pin G on transmission harness

harness connectors are recon-

connector P-C1 (WP 0018,

nected. Verify correct operation of

Figure 56) and pin 1 on transmis-

machine (TM 5-2410-241-10).

sion solenoid valve #3 connector

2. If continuity is NOT found, replace

P-C7 (WP 0018, Figure 73).

transmission sensor harness (WP

0173). Ensure all harness connec-

tors are reconnected. Verify cor-

rect operation of machine (TM 5-

2410-241-10).