TM 5-2410-240-10

0012

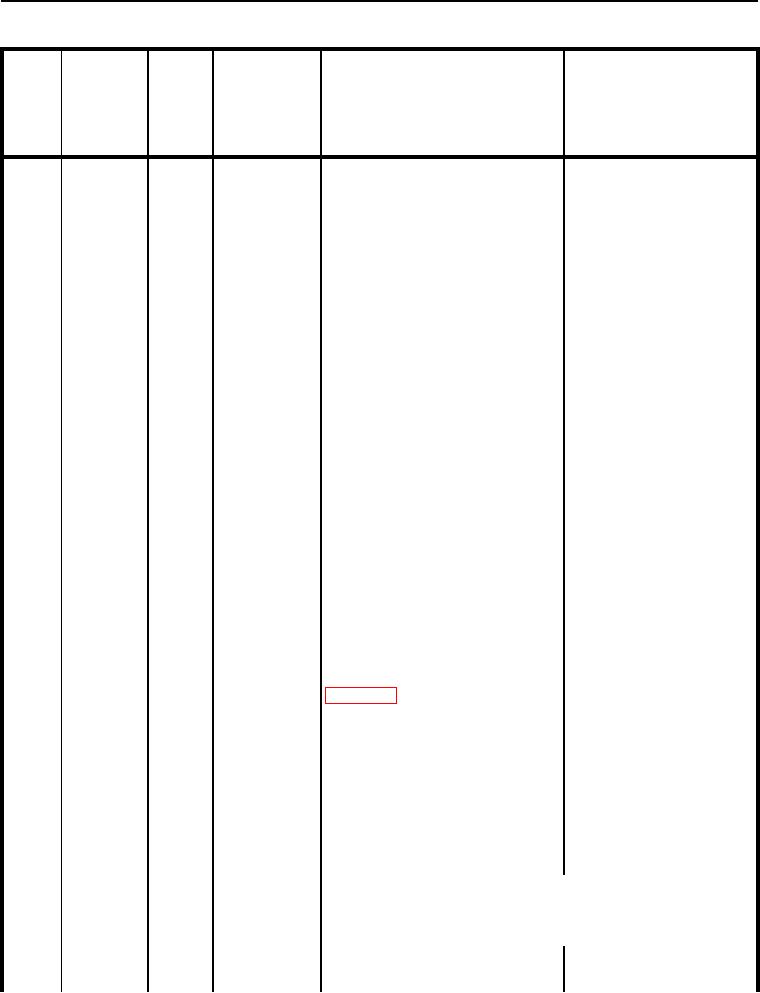

Table 1. Preventive Maintenance Checks and Services (PMCS) - Continued

LOCATION

ITEM TO BE

CHECKED

OR

EQUIPMENT NOT

ITEM

MAN-

NO.

INTERVAL HOURS

SERVICED

PROCEDURE

READY/AVAILABLE IF:

a. Move machine forward and test Brakes DO NOT slow/stop

31

During

Pedal

service brakes.

machine.

b. Check brake/deceleration pedal Pedal binds or does not

for binding and obstructions.

operate properly.

32

During

Drive Train

a. Monitor machine operation for

unusual noise or vibrations from

engine and hydrostatic drive train.

b. Listen for unusual squeaking or

squealing indicating dry track

joints.

c. Notify Field Maintenance if

unusual noises or vibrations are

present.

33

During

Dozer Blade

a. Monitor blade operation for

unusual noise or vibrations.

b. Notify Field Maintenance if

unusual noises or vibrations are

present.

34

During

Overall

Watch for evidence of fluid

Class III oil leaks are

Leakage

leakage.

evident. Any coolant or fuel

leak is evident.

35

During

Instrument

a. With machine fully warmed up

Indicators and gauges

Panel

monitor indicators, gauges and

indicate an abnormal

messenger display.

operation.

b. If action light indicator is on or

Action light indicator is on or

flashing, troubleshoot system

flashing.

36

During

Air Conditioner Check air conditioner or heater for

Damaged or does not

or Heater

damage and verify proper

operate if required for

operation.

mission.

37

During

Implement

a. Check blade and ripper for drift

Drift

during operation.

b. Notify Field Maintenance if

blade of ripper drifts during

operation.

N OT E

38

After

Overall View

Ensure machine is clean in order

to

facilitate

performance of PMCS inspections.

0012-20