TM 5-2410-240-23-1

0021

Table 2. Cab Troubleshooting With Codes. - Continued.

0021

CID FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

N OT E

2679-03 Blade Shake Switch Voltage

Above Normal

Always inspect harness connectors that are involved in circuit.

Poor connections can often be cause of an electrical circuit prob-

lem. Verify that all connections in circuit are clean and secure,

and connections are in good condition. If a problem with connec-

tion is found, correct problem and verify diagnostic code is active

before performing this procedure.

Tag wiring harnesses to aid installation.

Perform this test only if condition is active.

1. Turn ignition switch and

battery disconnect switch to

OFF position (TM 5-2410-240-

10).

2. Remove right joystick cover

(WP 0238).

3. Disconnect harness connec-

tor CA-C7 (WP 0018, Figure

73) from blade control handle

(WP 0018, Figure 78).

4. Using digital multimeter, test

Continuity Check Agrees With

blade shake switch (WP 0018,

Expected Results - Proceed to

Figure 78) for continuity (WP

step 5.

0283) between the following

Continuity Check Does Not

switch terminals at joystick

Agree With Expected Results -

harness connector:

Switch faulty and replace right joy-

a. Switch terminal 5 and

stick (WP 0240). Ensure all har-

terminal 7. Refer to

ness connectors are reconnected.

Table 11 for results.

Verify proper operation of machine

b. Switch terminal 5 and ter-

(TM 5-2410-240-10).

minal 6. Refer to Table 11

for results.

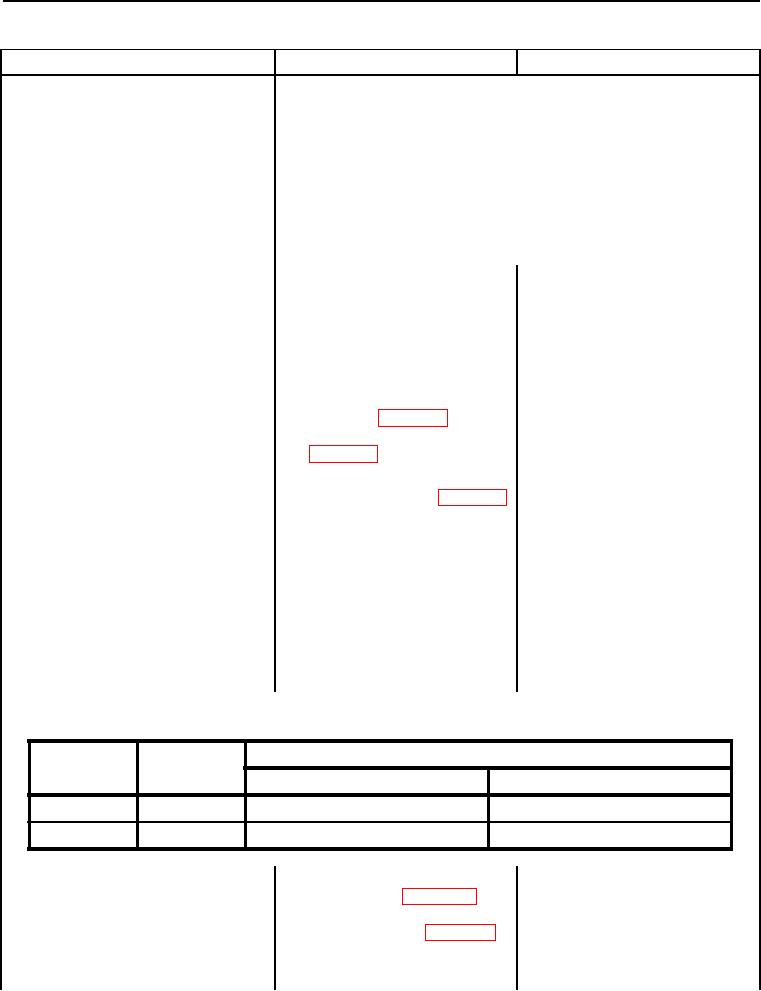

Table 11. Blade Shake Switch Table.

0021

Switch Acti-

Switch Posi-

Expected Results

vation

tion

Terminal 6 and Terminal 5

Terminal 7 and Terminal 5

Released

Up

No Continuity (open)

Continuity (closed)

Depressed

Down

Continuity (closed)

No Continuity (open)

5. Disconnect seat harness con-

nector CA-C1 (WP 0018, Fig-

ure 69) from harness

connector C-C24 (WP 0018,

Figure 26).