TM 5-2410-240-23-1

0028

AIR INLET AND EXHAUST SYSTEM INSPECTION CONTINUED

N OT E

Check valve is used to direct dust and dirt from pre-cleaner and out from exhaust system.

Check valve is also used to prevent exhaust from being directed toward pre-cleaner.

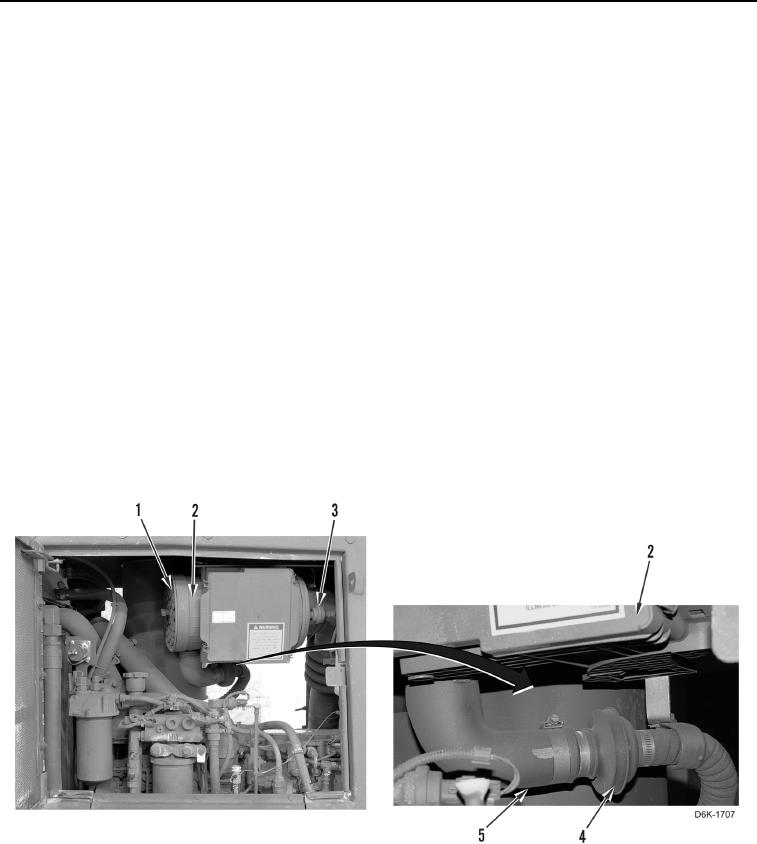

4. Inspect engine air cleaner elements, pre-cleaner (Figure 2, Item 1), and housing (Figure 2, Item 2) for the

following:

a. Inspect pre-cleaner (Figure 2, Item 1) for dirt and debris. If dirt accumulates on pre-cleaner or air filters are

prematurely plugged, inspect the check valve (Figure 2, Item 4) for correct operation by verifying air can

flow in only one direction on check valve (Figure 2, Item 4).

(1) Inspect hoses (Figure 2, Item 5) to check valve for damage, and replace if condition found (WP 0041).

(2) Replace muffler (WP 0045) if check valve and hoses test OK.

b. Inspect air cleaner housing (Figure 2, Item 2) for damage. If damage is found, inspect check valve for the

following:

(1) Correct installation and proper operation. Verify that air can flow in only one direction on check valve

(Figure 2, Item 4). If check valve tests OK, replace air cleaner housing (WP 0105).

(2) Dirt tracks visible on clean side of engine air cleaner element. If dirt tracks are observed, contaminants

are flowing past engine air cleaner element and/or seal for engine air cleaner element. Replace air fil-

ter elements (WP 0105).

(3) Inspect for dirt on clean side of air filter element, originating at air filter sensor (Figure 2, Item 3). If dirt

is entering from sensor, tighten or replace sensor (WP 0105).

Figure 2. Air Cleaner Housing and Check Valve.

0028

END OF TASK