TM 5-2410-241-23-1

0011

IMPLEMENT AND STEERING HYDRAULIC SYSTEM CONTINUED

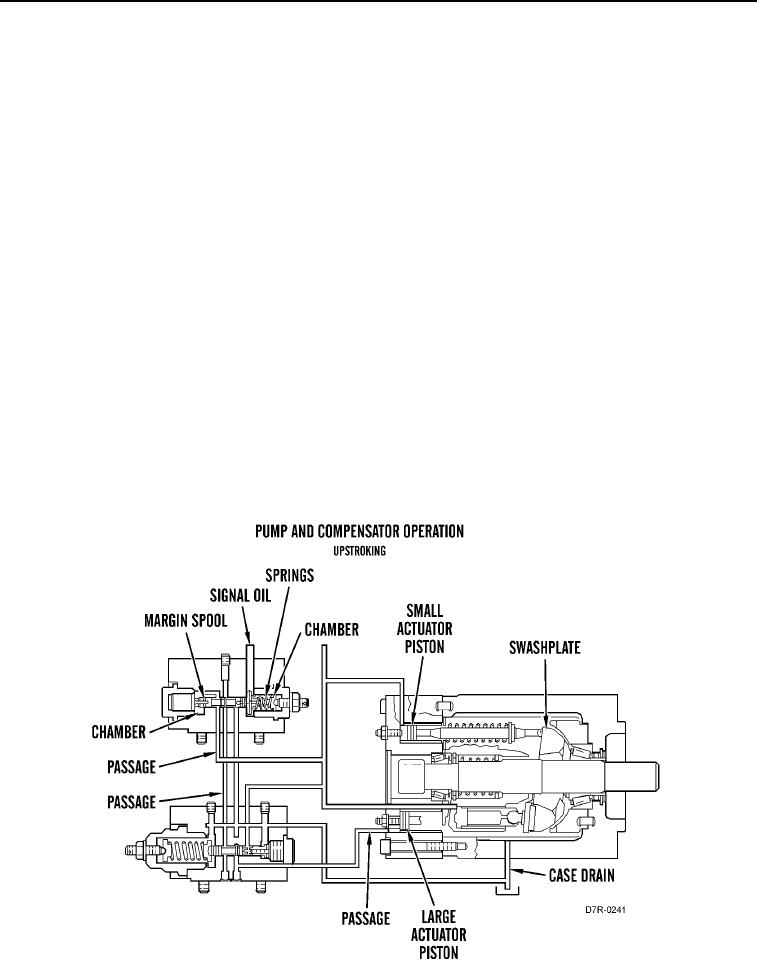

The following schematics show the actions of the pump and the compensator valve under different conditions in

the hydraulic system.

Upstroking

00011

Upstroking means that the pump is increasing the displacement (output) and occurs when the signal oil pressure

increases due to an increased load. The highest signal oil pressure from the control valves flows through the line

and the oil fills a chamber. The force of the signal oil pressure plus the force of the springs now move the margin

spool to the left. The spool movement blocks the flow of pump oil to the large actuator piston. The spool movement

also opens the passages to the large actuator piston to the case drain. The combined force -- of the actuator

spring and of the system oil pressure that is behind the small actuator piston -- moves the swashplate toward the

maximum angle (upstroke).

Pump output is increased by upstroking until the pressure in passage moves the margin spool right to the metering

position. When the margin spool is first at the metering position, system oil pressure in passage is higher than the

signal oil pressure and the force of springs in chamber. The greater pressure moves the margin spool farther to the

right. This sends system oil pressure through passages and to the large actuator piston.

Because the force of the large actuator piston is greater than the force of the small actuator piston, plus the force of

the actuator spring, the force that is on the swashplate toward the minimum angle is greater than the force that is

on the swashplate, toward the maximum angle. The difference in force causes a decrease in the angle of the

swashplate and the pump output. The decrease in the pump output causes a decrease in pressure. When the

pump flow decreases enough, the combined signal pressure and the force of springs in chamber cause the margin

spool to move to the left. The pump oil that is behind the large actuator piston flows to the case drain again. The

small actuator piston and the actuator spring increase the swashplate angle.

The continuous oscillation (metering) of margin spool maintains the system pressure in chamber at 305 psi

(2,100 kPa) higher than the signal pressure that is in the chamber, because the force of the springs is equal to

305 psi (2,100 kPa). The difference is called the margin pressure.

Figure 13. Pump and Compensator Operation (Upstroking).

0011