TM 5-2410-241-23-1

0011

IMPLEMENT AND STEERING HYDRAULIC SYSTEM CONTINUED

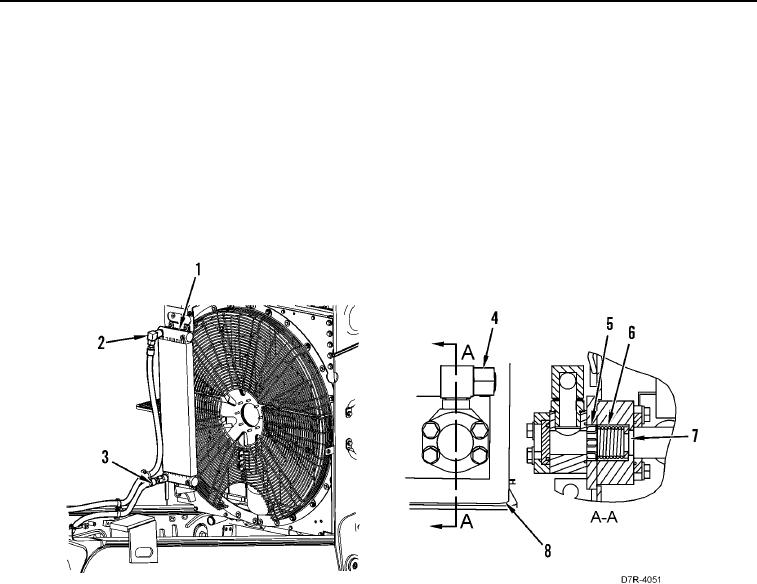

Oil Cooler and Bypass Valve

00011

The oil cooler bypass valve is installed at the port for the implement return oil (Figure 11, Item 3) and is located on

the hydraulic oil tank (Figure 11, Item 8). When the implement or steering circuits are active, the return oil flows

through the bypass valve. A valve (Figure 11, Item 5) and spring (Figure 11, Item 6) cause a back pressure of

approximately 39 psi (270 kPa), which causes the flow of part of the return oil through an outlet (Figure 11, Item 4)

to the oil cooler (Figure 11, Item 1). The larger part of the return oil flows through outlet (Figure 11, Item 7) to the

tank (Figure 11, Item 8). The bypass valve opens quickly in order to relieve the increases (surges) of flow of the

return oil. The bypass valve keeps pressure increases (spikes) from the oil cooler. The oil that flows out of the oil

cooler outlet (Figure 11, Item 2) is sent to the implement pump case and the steering motor case in order to

lubricate the pump and the motor.

Figure 11. Oil Cooler and Bypass Valve.

0011

Piston Pump (Implement)

00011

Engine Off

00011

The hydraulic pump for the implements and for the steering is an automatically controlled slipper type piston pump.

The pump senses pressure in order to determine the flow that is needed by the system.

When the drive shaft rotates, the cylinder barrel also turns. Nine pistons are held against the non-rotating

swashplate by the retaining plate. As illustrated, at the maximum swashplate angle, part of pistons are pulled out of

the cylinder barrel (not illustrated). The remaining pistons are pushed into the cylinder barrel. Rotation of the

cylinder barrel causes the pistons to move in and out of the cylinder barrel. Oil is pulled into the pump and oil is

pushed out of the pump by the push-pull movement of the pistons.

The angle of the swashplate determines the amount of oil that is pulled into each piston bore or is pushed out of

each piston bore by the drive shaft rotation.

There are infinite swashplate angle positions between the neutral angle (zero degrees) and the maximum angle. A

greater amount of oil is pulled into the pump and a greater amount of oil is pushed out of the pump by an increased

swashplate angle.

When the swashplate angle is zero degrees, pistons do not move in and out of the rotating cylinder barrel.

Therefore, no oil is pulled into the pump, no oil is pushed out of the pump and there is zero displacement from the

pump. This means the pump is not generating oil flow there is not a restriction to flow that can generate pressure.