TM 5-2410-241-23-1

0011

IMPLEMENT AND STEERING HYDRAULIC SYSTEM CONTINUED

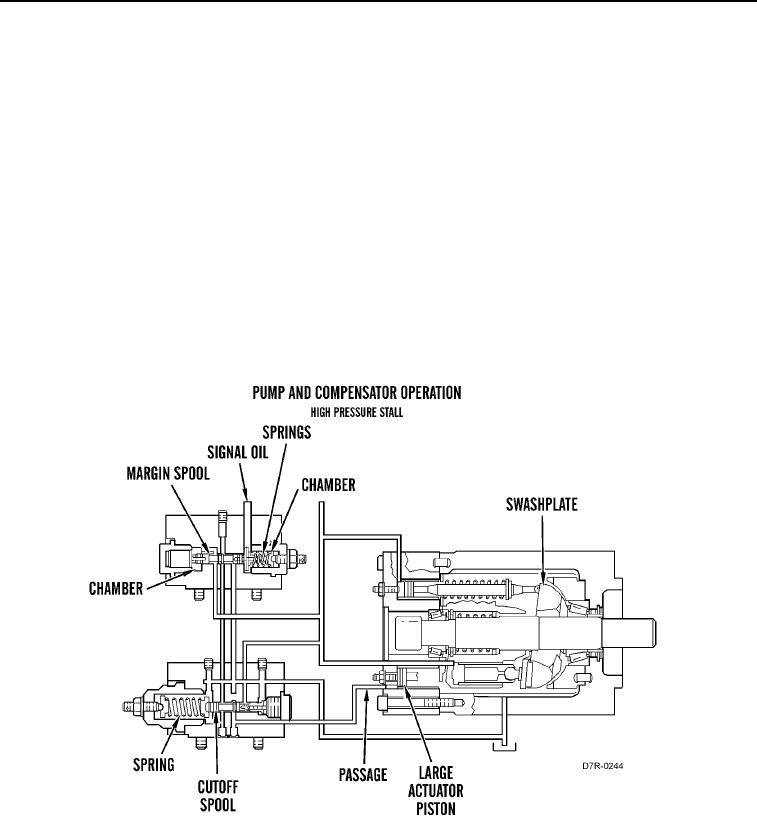

High Pressure Stall

00011

When the hydraulic system stalls under a load in the steering circuit, the oil pressure increases. A stall occurs

when system oil pressure gets to 5,585 psi (38,500 kPa). Signal oil pressure in the line and the chamber now

equals system oil pressure in the chamber. Springs keep the margin spool moved to the left which puts the pump in

an upstroking position. As system oil pressure approaches 5,585 psi (38,500 kPa), the pressure cutoff spool

moves to the left against the spring. Pump oil flows through passage to the large actuator piston. The pressure that

is behind the large actuator piston moves the swashplate until the system pressure is maintained at 5,585 psi

(38,500 kPa).

When the pump output flow is insufficient for maintaining the system pressure and the pressure decreases below

5,585 psi (38,500 kPa), the force of the spring moves the pressure cutoff spool further to the right. This spool

movement stops the flow of oil past the spool to the large actuator piston. As system pressure decreases further,

the pressure cutoff spool moves further to the right and the large piston actuator opens to the margin spool. When

system pressure approaches margin pressure over signal oil pressure, the margin spool moves to the metering

position. The metering position allows the swashplate angle to increase until pump flow is sufficient to make up

system leakage and the lower required pressure is maintained. If there is no signal oil pressure, system pressure

goes to low pressure standby.

Figure 16. Pump and Compensator Operation (High Pressure Stall).

0011