TM 5-2410-241-23-1

0011

IMPLEMENT AND STEERING HYDRAULIC SYSTEM CONTINUED

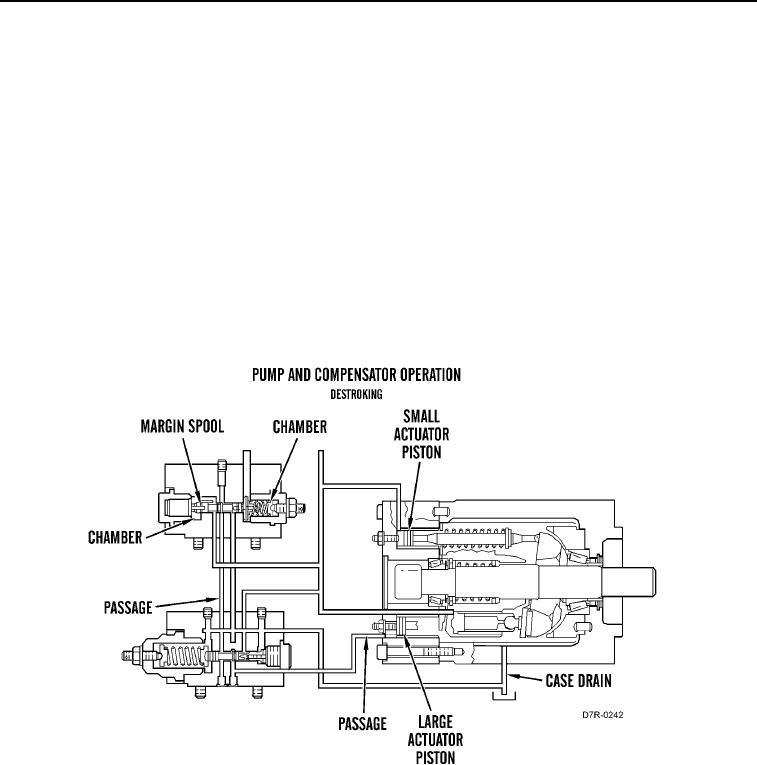

Destroking

00011

Destroking means that the pump is decreasing the displacement (output) and occurs when the signal oil pressure

decreases from lower loads. Destroking also occurs when all of the control valves are in the HOLD position and

signal oil pressure decreases to 0 psi (0 kPa). The lower signal oil pressure in the chamber causes the higher

system oil pressure in the chamber to move the margin spool to the right. The spool movement allows the system

oil pressure to flow through passages and to the large actuator piston. The force that is created by the system oil

pressure (that is behind large actuator piston) is now higher than the force of the actuator spring, and the system

oil pressure (that is behind small actuator piston). The angle of the swashplate decreases.

Pump output decreases until the pump flow is not adequate to maintain system pressure, and system pressure

decreases. When system pressure approaches 305 psi (2,100 kPa) (margin pressure) above the signal oil

pressure, the margin spool moves to the left, and the spool begins to meter oil at the large actuator piston to case

drain. When system pressure approaches 525 psi (3,600 kPa) (low pressure standby), the margin spool moves to

the left and the spool begins to meter oil at the large actuator piston to the case drain. Signal oil pressure is zero

when the control valves are in the HOLD position. The swashplate increases the angle slightly, so that the pump

output makes up system leakage. Also, the higher swashplate angle maintains the margin pressure in the system.

Figure 14. Pump and Compensator Operation (Destroking).

0011