TM 5-2410-241-23-1

0020

Table 1. Powertrain Troubleshooting Procedures - Continued.

0020

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1402-6 Transmission Sole-

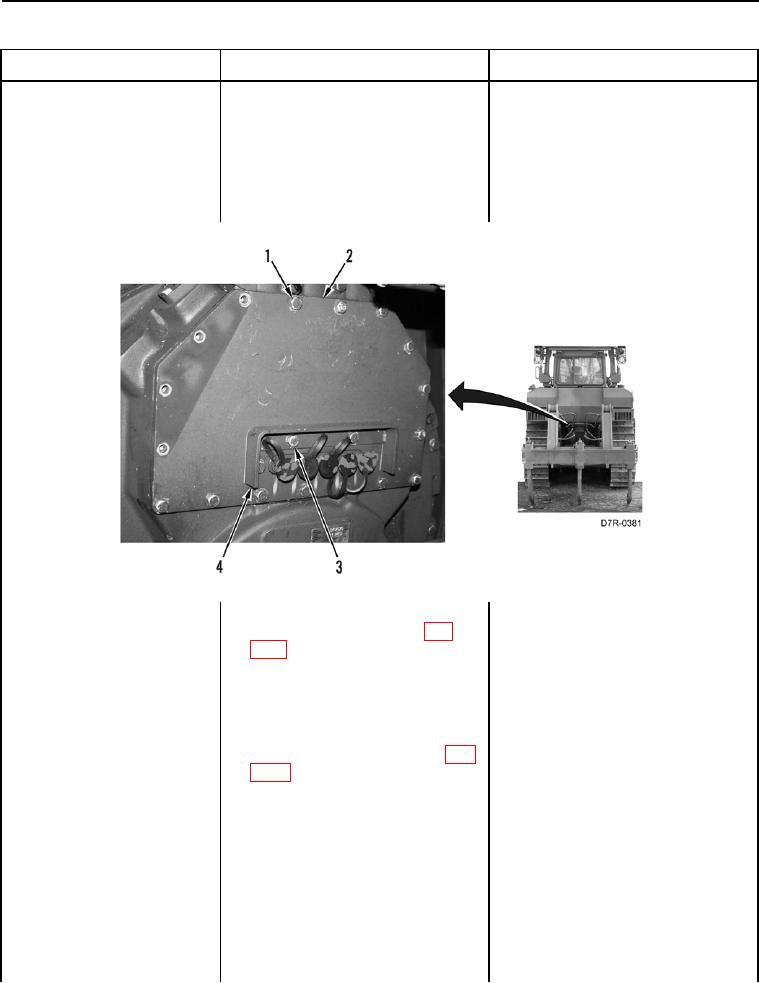

4. Remove two bolts (Figure 51,

noid Valve #2 Current

Item 3) and guard (Figure 51,

Above Normal - Contin-

Item 4) from machine.

ued

5. Remove 15 bolts (Figure 51,

Item 1) and plate (Figure 51,

Item 2) from machine.

Figure 51. Guard, Plate, and Retaining Hardware.

0020

6. Disconnect transmission solenoid

valve #2 connector P-C3 (WP

0018, Figure 72) from transmis-

sion solenoid valve #2 (WP 0145).

7. Turn ignition switch and battery

disconnect switch to ON position

(TM 5-2410-241-10).

8. Check for Diagnostic Codes (WP

1. If active 1402-5 code is present,

replace transmission solenoid

valve #2 (WP 0145). Ensure all

harness connectors are recon-

nected. Verify correct operation of

machine (TM 5-2410-241-10).

2. If active 1402-6 code is present,

proceed to step 9.

9. Turn ignition switch and battery

disconnect switch to OFF position

(TM 5-2410-241-10).