TM 5-2410-241-23-1

0033

IMPLEMENT PUMP DISCHARGE TESTS CONTINUED

High Pressure Cutoff - Continued

0033

54. Start machine and allow it to run for 15 minutes to reach normal operating temperature (TM 5-2410-241-10).

55. Release parking brake (TM 5-2410-241-10).

56. Ensure implement lockout switch is in the LOCK position (TM 5-2410-241-10)

57. Set machine to HIGH IDLE (RABBIT MODE) on the throttle switch (TM 5-2410-241-10).

58. Apply service brake (TM 5-2410-241-10).

59. Slowly apply steering control handle to MID STEER LEFT position (TM 5-2410-241-10).

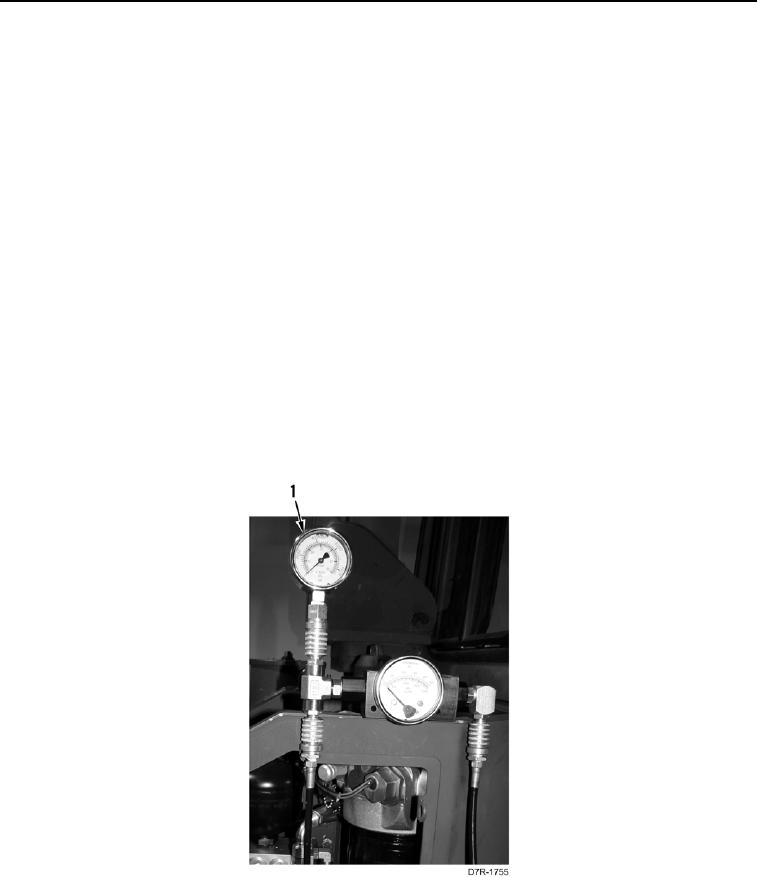

60. Pressure gauge (Figure 9, Item 1) should read 5,485 to 5,685 psi (37,800 to 39,200 kPa). Record pressure

readings on gauge.

a. If pressure is out of specification, repeat steps 47 through 53.

b. If pressure is within specification, proceed to step 61.

61. Return steering control handle to NEUTRAL STEER position (TM 5-2410-241-10).

62. Release service brake (TM 5-2410-241-10).

63. Set machine to LOW IDLE (TURTLE MODE) on the throttle switch (TM 5-2410-241-10).

64. Apply parking brake (TM 5-2410-241-10).

65. Turn ignition switch and battery disconnect switch to OFF position (TM 5-2410-241-10).

66. Install front floor plate (WP 0230).

67. Remove test equipment from machine.

Figure 9. Pressure Cutoff.

0033

END OF TASK

END OF WORK PACKAGE