TM 5-2410-241-23-1

0039

Table 1. Preventive Maintenance Checks and Services (PMCS) - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

NOT FULLY MISSION

SERVICE

NO.

INTERVAL

PROCEDURE

CAPABLE IF:

13

Every 500

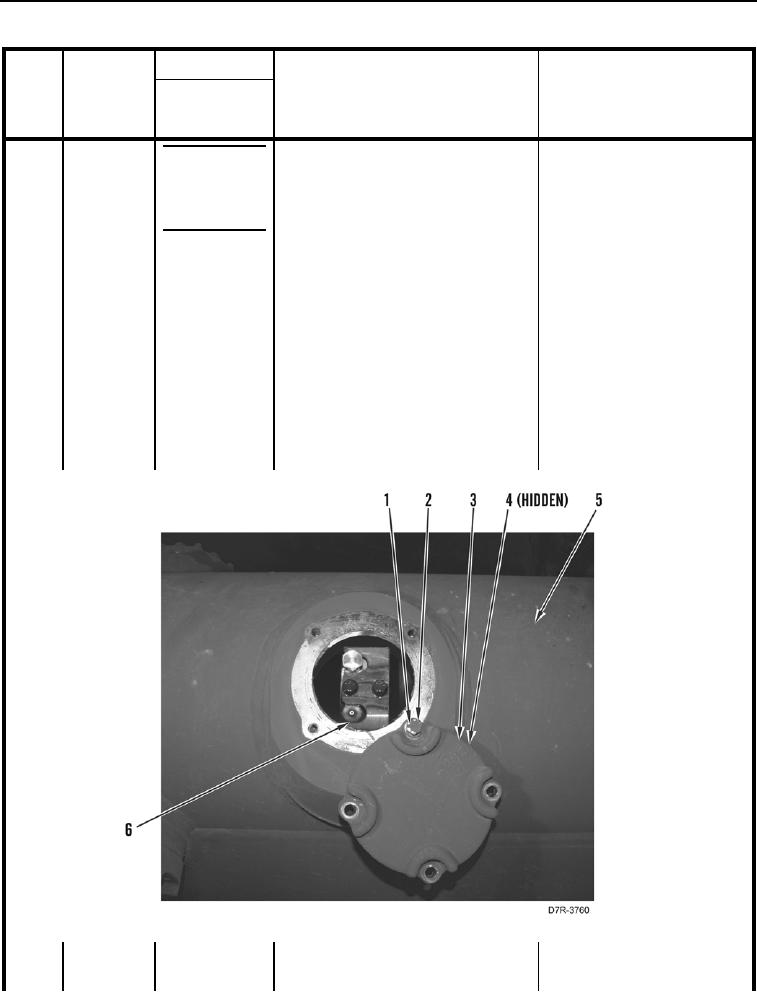

b. Remove four bolts (Figure 6,

Recoil Spring Compartment oil

Recoil Spring

(Cont.) Service

Item 1), washers (Figure 6, Item 2), O- level low.

Compartment

Hours or 3

ring (Figure 6, Item 4) and cover plate

Oil Level -

months

(Figure 6, Item 3) from track roller

Check

frame (Figure 6, Item 5). Discard O-

ring.

c. Maintain oil level to the bottom of

flange (Figure 6, Item 6). Refer to

LO 5-2410-241-13 for proper type and

quantity of oil.

d. Install new O-ring (Figure 6, Item 4,

cover plate (Figure 6, Item 3), four

washers (Figure 6, Item 2), and bolts

(Figure 6, Item 1) on track roller frame

(Figure 6, Item 5).

e. Repeat steps for other recoil spring

compartment.

Figure 6. Recoil Spring Oil Level.

0039