TM 5-2410-240-23-1

0031

DECELERATION/BRAKE PEDAL TEST - HYDRAULIC CONTINUED

The machine uses hydrostatic powertrain and engine deceleration for braking. The machine also has an electro-

hydraulic controlled parking brake system. Machine ECM controls both of these systems using input from operator

controlled brake/deceleration pedal. This is useful when technician checks function of hydrostatic components.

Refer to WP 0007 for detailed description of hydrostatic pumps and motors.

This test determines whether brakes are adjusted properly. Machine must be supported and tracks off ground to

perform this test (WP 0281).

Setup

00031

1. Inspect hydraulic system for Class III leakage and damage. Hydraulic lines must be free from kinks, sharp

bends, and restrictions.

2. Turn ignition switch to OFF position (TM 5-2410-240-10).

3. Connect MSD to machine (WP 0016).

4. Turn battery disconnect switch to ON position (TM 5-2410-240-10).

5. Turn ignition switch to ON position. Start ET and select machine control ECM.

N OT E

Wait at least 30 seconds for diagnostic codes to become active.

6. Monitor active diagnostic codes with ET. Check and record any active diagnostic codes. If diagnostic codes are

set, refer to WP 0013.

7. Operate machine until hydraulic system oil temperature is at least 104F 9F (40 5C).

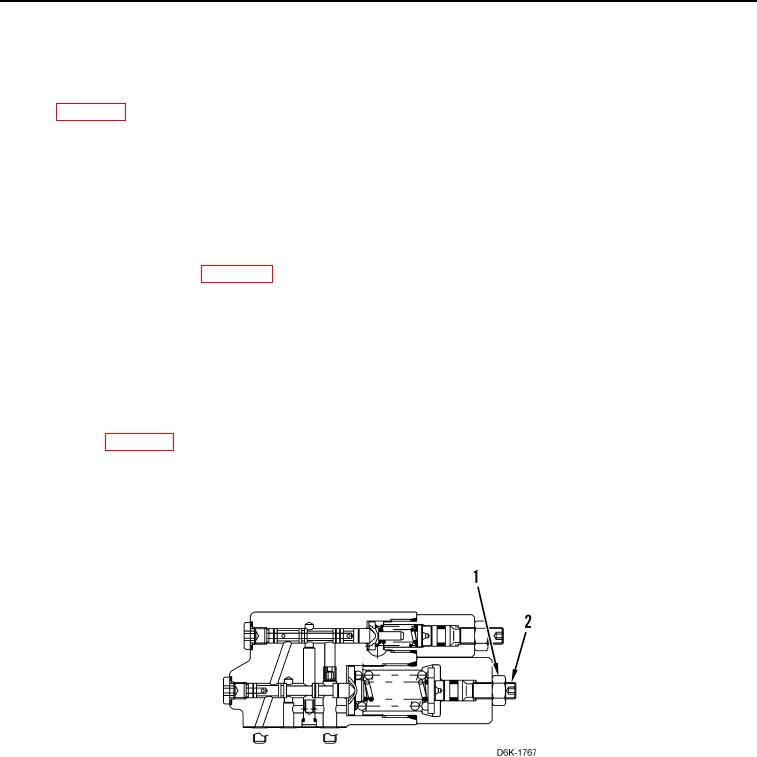

8. Stop engine and relieve hydraulic system pressure (WP 0162), and install pressure gauge at parking brake

pressure tap (Figure 13, Item 2) on test panel (Figure 13, Item 1). Refer to WP 0291 for pressure gauge and

hose setup.

Figure 13. Test Panel.

0031

9. Lift and support machine high enough so that tracks do not touch ground (WP 0281).