TM 5-2410-241-23-1

0032

RIPPER LIFT CYLINDER PRESSURE TEST - CONTINUED

00032

8. Start machine and allow it to run for 15 minutes to reach normal operating temperature (TM 5-2410-241-10).

9. Set machine to HIGH IDLE (RABBIT MODE) on the throttle switch (TM 5-2410-241-10).

10. Slowly engage ripper control to the FULL LIFT position (TM 5-2410-241-10).

N OT E

Do not hold control lever in the LIFT position longer than 15 to 20 seconds.

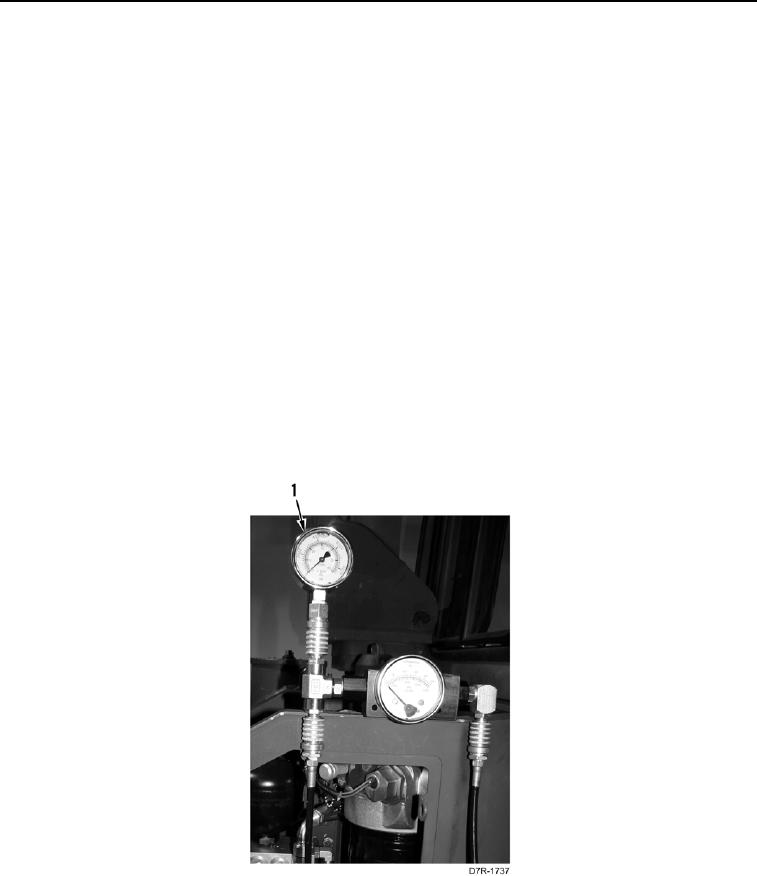

11. Hold ripper lift control in the FULL LIFT position (TM 5-2410-241-10) and record pressure shown on the pres-

sure gauge (Figure 11, Item 1).

12. Pressure gauge (Figure 11, Item 1) should read 3,255 to 3,345 psi (22,450 to 23,050 kPa). If pressure is out of

specification, replace ripper lift control valve (WP 0211).

13. Set machine to LOW IDLE (TURTLE MODE) on the throttle switch (TM 5-2410-241-10).

14. Lower ripper to the ground (TM 5-2410-241-10).

15. Turn ignition switch and battery disconnect switch to OFF position (TM 5-2410-241-10).

16. Release hydraulic system pressure (WP 0186).

17. Remove gauges.

18. Reinstall protective caps.

19. Close door (TM 5-2410-241-10).

Figure 11. Test Equipment Installation.

0032

END OF TASK