TM 5-2410-240-23-1

0019

Table 2. Engine Troubleshooting with Codes - Continued.

0019

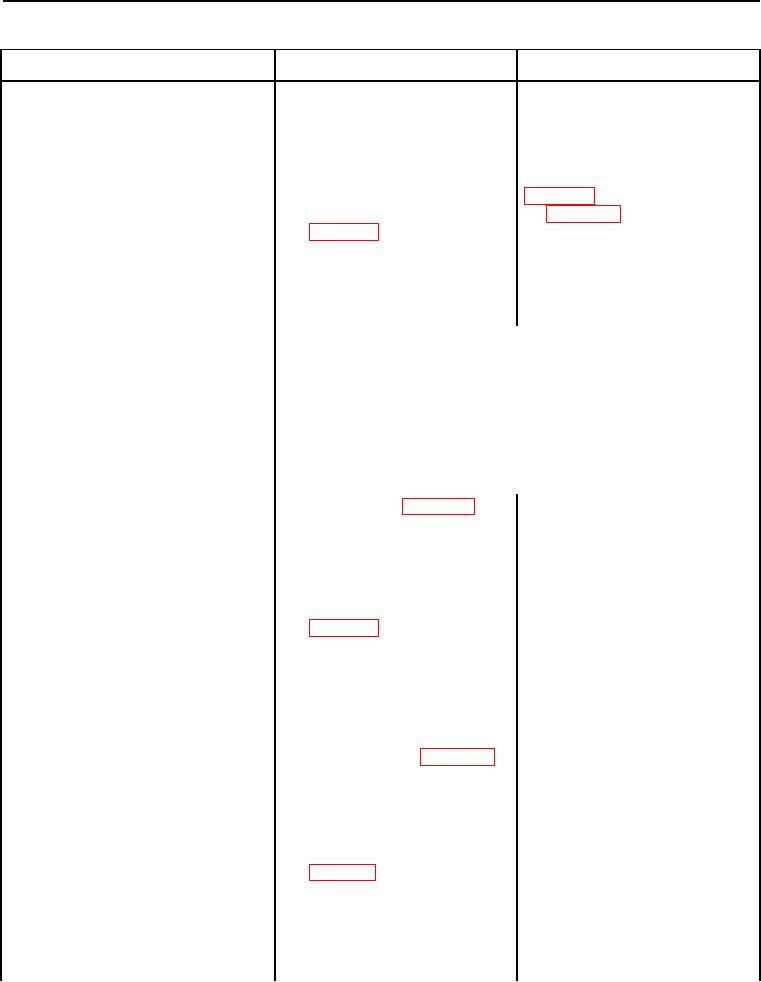

CID FMI CODE

TEST OR INSPECTION

CORRECTIVE ACTION

0268-02 Programmed Parameter

2. Start and run engine (TM 5-

0268-02 Active - Proceed to

Fault Erratic, Intermittent, or Incor-

2410-240-10), and verify

step 3.

rect Continued

0268-02 is active.

0268-02 Not Active - Return

machine to service.

Program the engine ECM

3. Verify machine ECM software

(WP 0017) and load injector trim

part number is correct, refer to

file (WP 0026). Verify proper oper-

ECM Programming

ation of machine (TM 5-2410-240-

10).

0342-08 Speed (Injection Pump Posi- Test Step 1: Test Signal Circuit.

tion) Sensor Abnormal Frequency,

Pulse Width, or Period

N OT E

Always inspect harness connectors that are involved in circuit.

Poor connections can often be the cause of an electrical circuit

problem. Verify that all connections in circuit are clean and

secure, and connections are in good condition. If a problem with

connection is found, correct the problem and verify diagnostic

code is active before performing this procedure.

Tag wiring harnesses to aid installation.

1. Connect MSD (WP 0016).

0041-03 or 0041-04 Active - Diag-

Select engine ECM C6.6 D6K

nose and repair active code as

and verify 0041-03 or 0041-04

outlined in this work package.

is active.

Code NOT Active - Proceed to

step 2.

2. Verify 0342-08 is active

0342-08 Active - Proceed to step

3.

No Active Code - Return machine

to service.

3. Turn ignition and battery dis-

connect switch to OFF posi-

tion (TM 5-2410-240-10).

4. Disconnect E-C3 (WP 0018,

Figure 104) harness connec-

tor from speed (injection pump

position) sensor.

5. Disconnect engine ECM har-

ness connector E-C1

(WP 0018, Figure 102) from

engine ECM J2.