TM 5-2410-240-23-1

0020

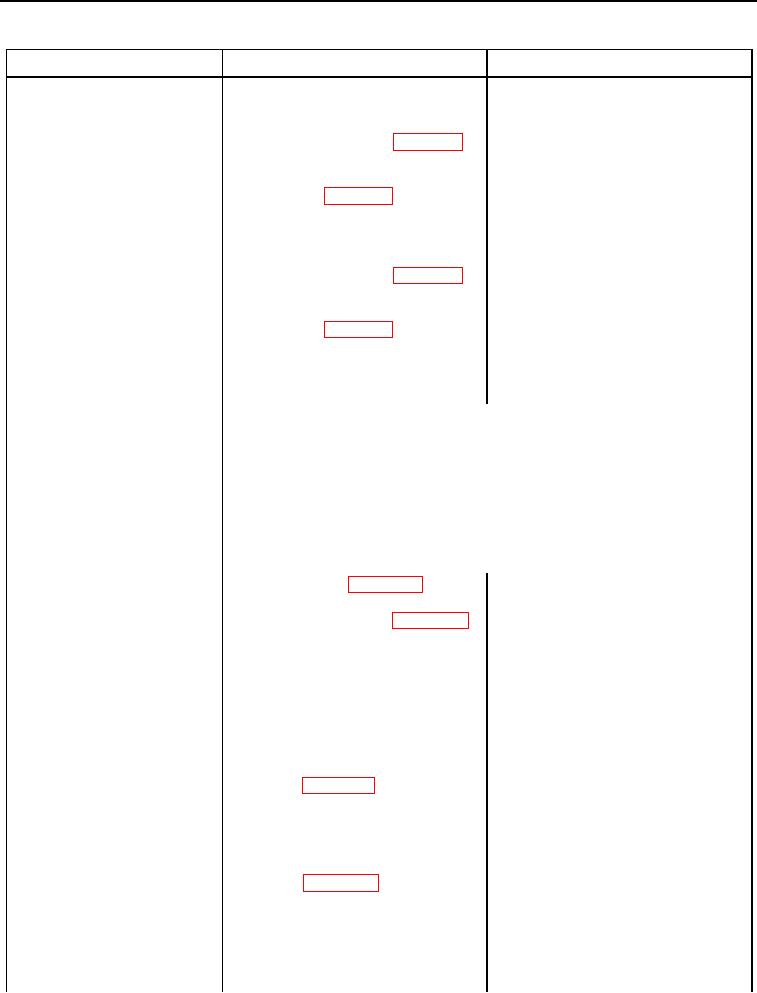

Table 2. Powertrain and Chassis Troubleshooting with Codes - Continued.

CID FMI CODE

Test or Inspection

Corrective Action

1708-03 Proportional Sole-

10. Using digital multimeter (WP

No Continuity - Proceed to step 11.

noid Valve (Right Drive

0283), test for continuity between

Continuity - Replace platform wiring

Motor) Voltage Above Nor-

pin 59 on platform harness ECM

harness (WP 0150, WP 0155).

mal - Continued

J1 connector PL-C4 (WP 0018,

Ensure all harness connectors are

Figure 217) and all other pins on

reconnected. Verify proper operation

platform harness ECM J1 connec-

of machine (TM 5-2410-240-10).

tor PL-C4 (WP 0018, Figure 217).

11. Using digital multimeter (WP

No Continuity - Replace machine

0283), test for continuity between

ECM (WP 0147, WP 0149). Ensure all

pin 59 on platform harness ECM

harness connectors are reconnected.

J1 connector PL-C4 (WP 0018,

Verify proper operation of machine

Figure 217) and all other pins on

(TM 5-2410-240-10).

platform harness ECM J2 connec-

Continuity - Replace platform wiring

tor PL-C5 (WP 0018, Figure 218).

harness (WP 0150, WP 0155).

Ensure all harness connectors are

reconnected. Verify proper operation

of machine (TM 5-2410-240-10).

N OT E

1708-05 Proportional Sole-

noid Valve (Right Drive

Always inspect harness connectors that are involved in circuit. Poor

Motor) Current Below Nor-

connections can often be the cause of an electrical circuit problem.

mal

Verify that all connections in circuit are clean, secure, and connections

are in good condition. If a problem with connection is found, correct

problem and verify diagnostic code is active before performing this

procedure.

Tag wiring harnesses to aid installation.

1. Connect MSD (WP 0016). Select

1708-05 Code Active - Proceed to

machine control ECM and check

step 2.

for diagnostic codes (WP 0013).

No Codes Active - The problem does

not exist at this time. Resume normal

operation.

2. Turn ignition switch and battery

disconnect switch to OFF position

(TM 5-2410-240-10).

3. Disconnect pump harness RH

drive motor solenoid connector

CH-C5 (WP 0018, Figure 84) from

RH drive motor solenoid.

4. Install a jumper wire between pins

1 and 2 on pump harness RH

drive motor solenoid connector

CH-C5 (WP 0018, Figure 84).