TM 5-2410-241-23-1

0032

RIPPER TILT CYLINDER DRIFT TEST

1. Start machine and allow it to run for 15 minutes to reach normal operating temperature (TM 5-2410-241-10).

2. Engage ripper lift control to lift ripper 2 feet (0.6 m) off ground (TM 5-2410-241-10).

3. Engage ripper tilt control to position ripper to FULL OUT TILT position.

4. Turn ignition switch and battery disconnect switch to OFF position (TM 5-2410-241-10).

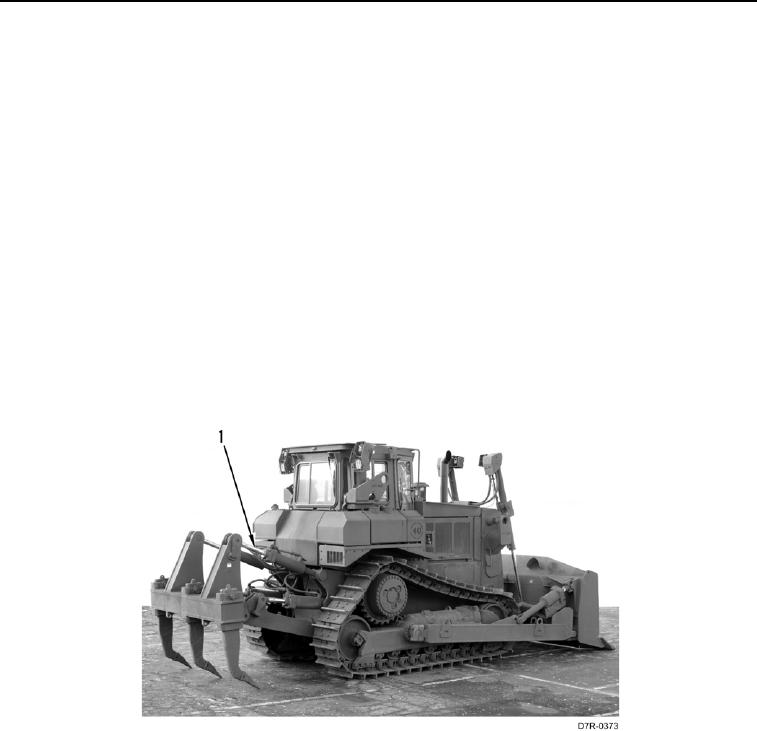

5. Measure length of tilt cylinder shaft (Figure 18, Item 1) and mark shaft at midpoint.

6. Start machine (TM 5-2410-241-10).

7. Engage ripper tilt control to tilt ripper to marked position (TM 5-2410-241-10).

8. Engage ripper lift control to lower ripper and raise machine off the ground (TM 5-2410-241-10).

9. Turn ignition switch and battery disconnect switch to OFF position (TM 5-2410-241-10).

10. Cylinder shaft (Figure 18, Item 1) should NOT DRIFT OVER 1/2 inch (12.7 mm) within 5 minutes or less. If

cylinders DRIFT OVER 1/2 inch (12.7 mm) within 5 minutes, replace ripper tilt cylinders (WP 0278).

11. Start machine (TM 5-2410-241-10).

12. Engage ripper lift control to raise ripper and lower machine to the ground (TM 5-2410-241-10).

13. Engage ripper tilt control and lift control to rest ripper frame on the ground (TM 5-2410-241-10).

14. Turn ignition switch and battery disconnect switch to OFF position (TM 5-2410-241-10).

Figure 18. Ripper Tilt Cylinder Drift Test.

0032

END OF TASK

END OF WORK PACKAGE