TM 5-2410-240-23-2

0157

BULKHEAD BRACKET INSTALLATION

000157

WARN I N G

Lubricating/hydraulic oils used in performance of maintenance can be very slippery.

Immediately wipe up any spills. Failure to follow this warning may result in injury to

personnel.

N OT E

Hydraulic hoses, tubes, fittings, and clamps are all installed using the same general

method. This procedure covers removal of one hydraulic tube assembly from machine.

Install tubes as noted during removal.

Brackets are all installed using the same general method. This procedure covers

installation of one bracket on machine. Repeat steps to install bracket on opposite side of

machine.

1. Position bracket (Figure 11, Item 4) on three tubes (Figure 11, Item 3) and install two washers (Figure 11,

Item 6), bolts (Figure 11, Item 5), and bracket (Figure 11, Item 4) on machine.

2. Install three bulkhead nuts (Figure 11, Item 2) on three tubes (Figure 11, Item 3).

3. Install three new O-rings (Figure 11, Item 7) and connect three hose fittings (Figure 11, Item 1) to three tubes

(Figure 11, Item 3).

RIGHT SIDE ANGLE AND TILT TUBES INSTALLATION

000157

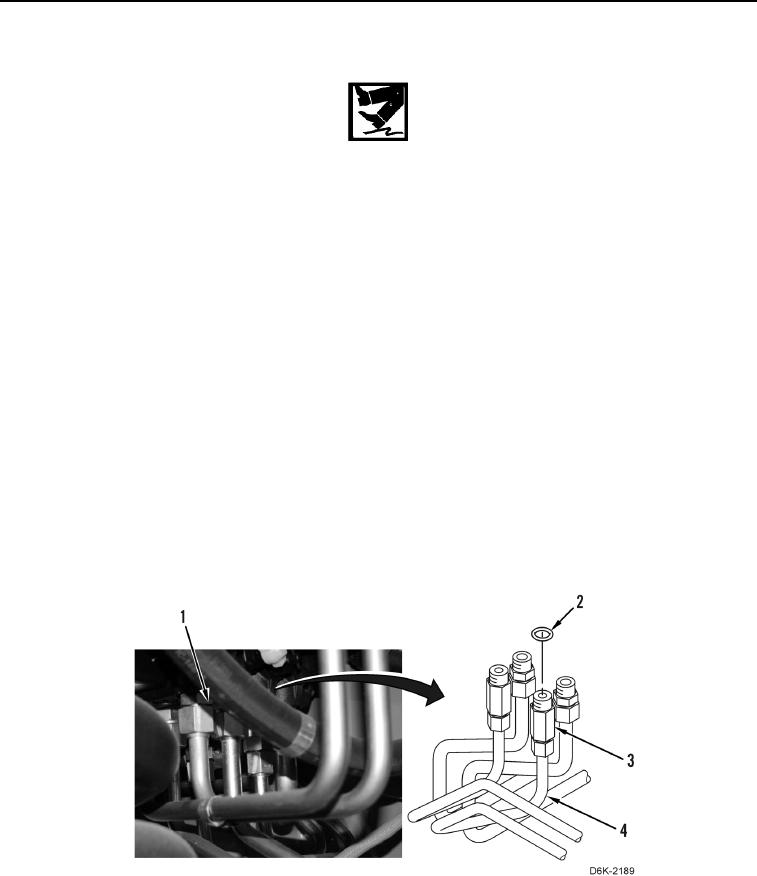

1. Remove caps and install two new O-rings (Figure 12, Item 2) on two tube nuts (Figure 12, Item 3).

2. Position two tubes (Figure 12, Item 4) on machine and install tube nut (Figure 12, Item 3) on valve bank

(Figure 12, Item 1) finger-tight.

Figure 12. Tube Assembly.

0157