TM 5-2410-241-23-3

0212

REMOVAL

000212

WARN I N G

Contact with oil can damage skin. Wear gloves when handling oil. If oil contacts skin, wash

it off immediately.

Lubricating oil is very slippery. Immediately wipe up any spills.

Failure to follow these warningsmay cause injury to personnel.

N OT E

Care must be taken to ensure that fluidsare contained during performance of inspection,

maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid

with suitable containers before opening any compartment or disassembling any

component containing fluids.

Dispose of all fluids accordingto local regulations and mandates.

Perform disassembly on a clean surface.

Clean exterior of component to prevent contamination.

Plug all lines, hoses and tubes to prevent contamination and leaks.

Tag and mark all electrical connectors, hoses, and lines to aid installation.

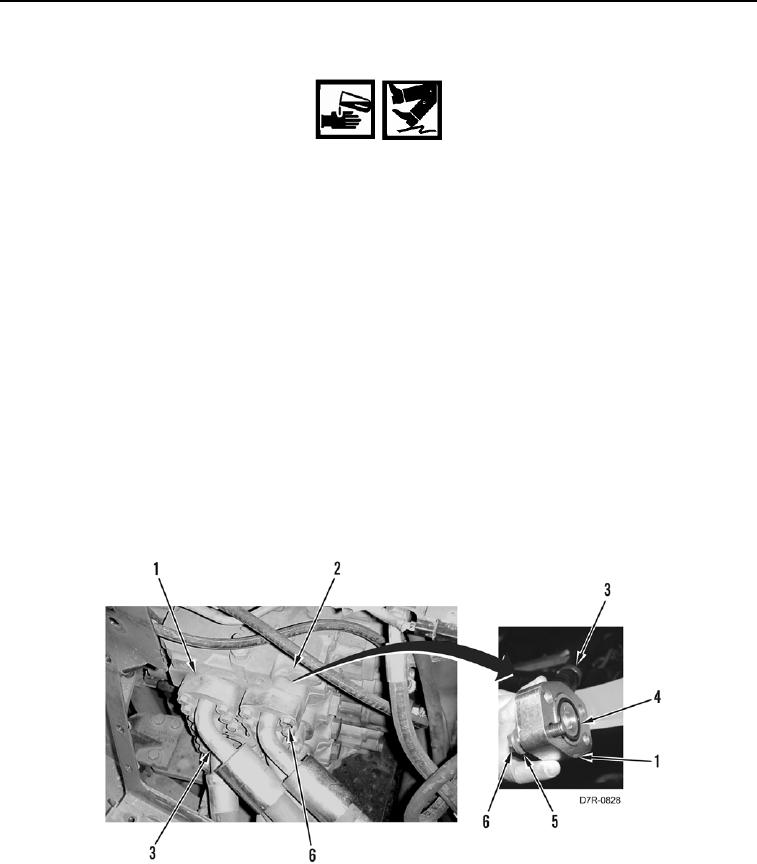

1. Remove 32 bolts (Figure 1, Item 6), washers (Figure 1, Item 5), 16 flanges (Figure 1, Item 1), and eight hoses

(Figure 1, Item 3) from valve bank (Figure 1, Item 2).

2. Remove eight O-rings (Figure 1, Item 4) from hoses (Figure 1, Item 3). Discard O-rings.

Figure 1. Hose Removal from Valve Bank.

0212