52

TM 5-2410-241-23-1

FIELD MAINTENANCE

-

THEORY OF OPERATION: IMPLEMENT AND STEERING HYDRAULIC

0

011

IMPLEMENT AND STEERING HYDRAULIC SYSTEM

00011

The hydraulic system controls the steering, the bulldozer, and the ripper or winch (depending on which implement

is installed). The hydraulic system is a load sensing, pressure compensated system. In a load sensing, pressure

compensated system, oil flow does not change according to the load conditions. Cylinder speeds remain constant

under all load conditions.

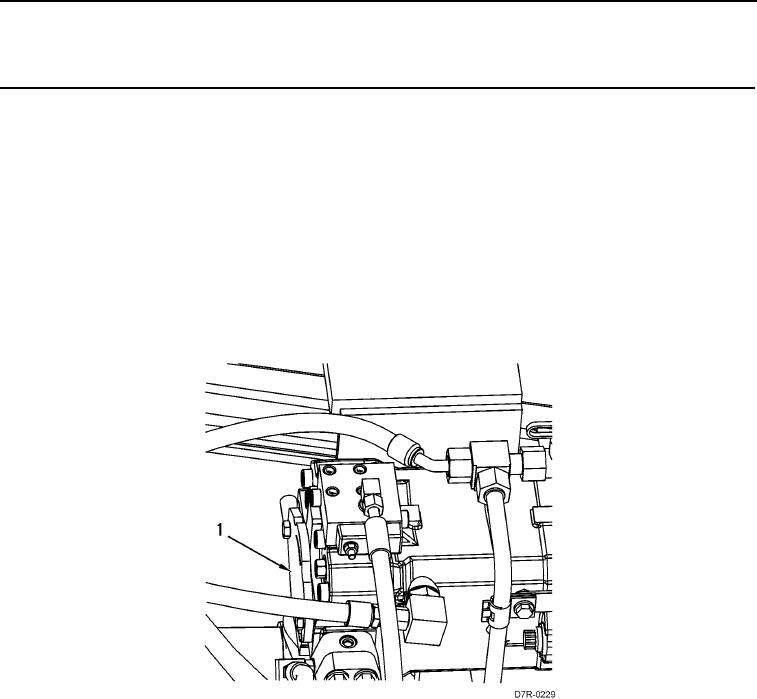

Hydraulic pump (Figure 1, Item 1) is a variable displacement piston pump. The pump provides oil for all implement

circuits and for the steering circuit. The pump is oversized so that the steering circuit and the implement circuit can

be operated simultaneously. The maximum pump flow is set at 76 US gal/min (289 L/min).

The pump destrokes to keep the pressure in the system at a minimum. When a control lever is moved to an

operating position, higher oil pressure is needed in the system. The destroked pump compensates for system

leakage with a small output and maintains an approximate system pressure of 525 psi (3,620 kPa).

Figure 1. Hydraulic Pump.

0011